Re-imagining Heat Regulation Systems

Introduction

Testing Without Limitations

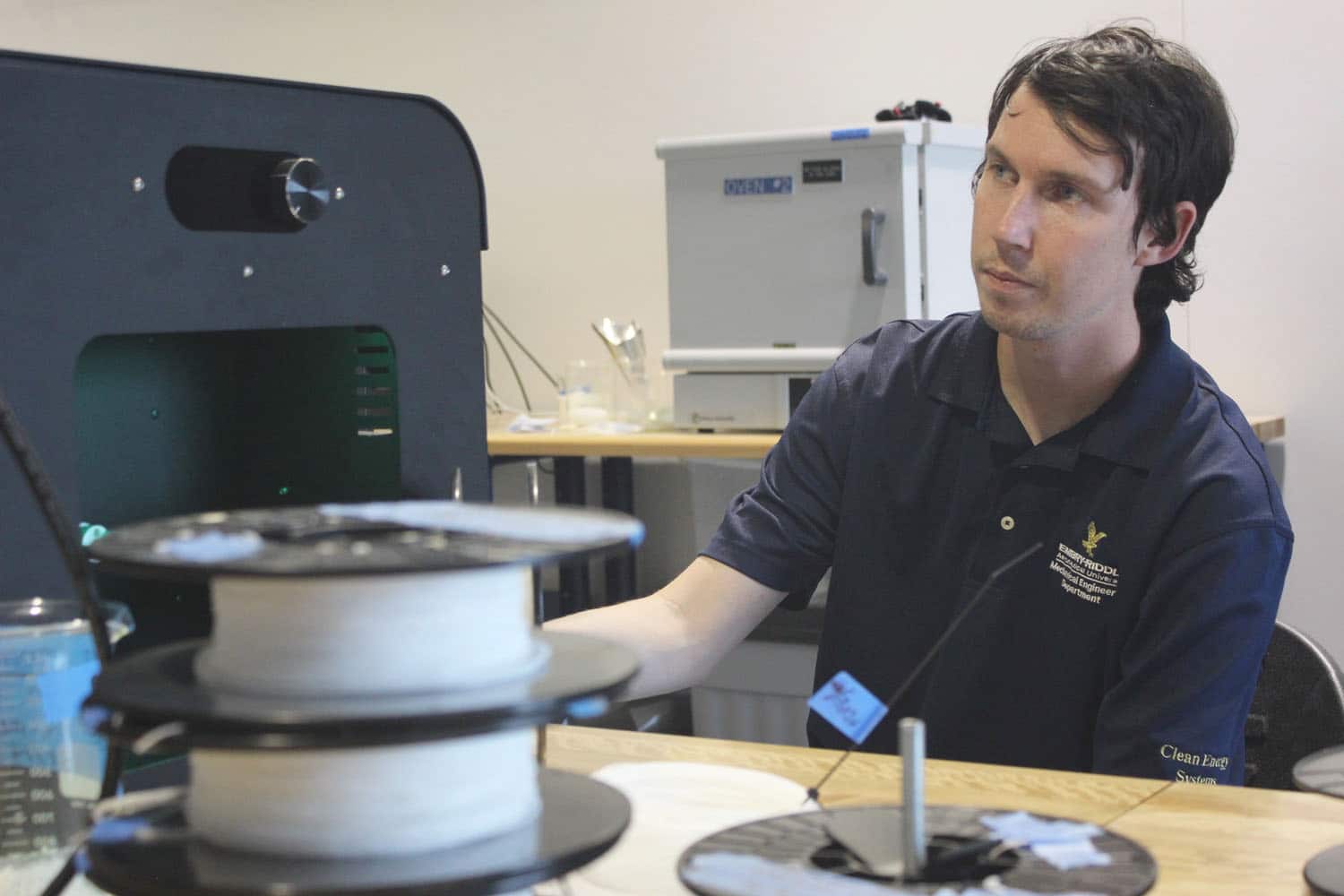

Researchers at Embry-Riddle Aeronautical University have embarked on an ambitious project – creating a self-contained, cost-effective, 3D printable heat sink by combining phase-change materials with plastics. The Composer Filament Maker is taking them closer to making that vision a reality.

Background

Ranking among America’s top aviation schools since 1925, Embry-Riddle Aeronautical University offers a variety of programs in aviation, applied science, engineering, computers and business. Its Mechanical Engineering Department is currently involved in groundbreaking research on battery cooling systems. Here, researchers are using the 3devo Composer Filament Maker to mix plastics and phase-change materials (PCM) into high-quality filament that can potentially 3D print lightweight, self-contained heat sinks.

The Challenge

To realize their vision of developing 3D printable heat sinks, Embry-Riddle researchers needed PCM-based filament that could hold a stable shape. They tried creating PCM-plastic composites using a filament extruder from a leading desktop extrusion company. But this machine could only let them achieve 20% PCM in their filament. It also did not offer the quality or customizability they needed.

The Solution

After considering all available alternatives, the researchers picked the 3devo Composer Filament Maker for several reasons. Firstly, it let them produce high-quality filament with excellent diameter control, even when working with non-typical materials. It also enabled experimentation with different PCM ratios and a variety of plastics. Further, it was the most cost-effective option available, meeting all their requirements without the need for any add-ons.

Get the Full Embry-Riddle

Customer Story

Customer Story

“3devo’s filament maker allows us to easily shift between materials, without the limitation of complex polymers holding us back. We have mixed various materials together such as phase-change materials mixed with HDPE and PLA.”

Sandra Boetcher

Associate Professor of Mechanical Engineering at Embry-Riddle

Workflow Highlights

Helping Embry-Riddle researchers develop new-age heat sinks

- High-quality filament with 3X higher PCM levels than before

The Composer Filament Maker has already produced PCM-HDPE filament with 60% PCM. This is 3 times higher than what their previous extruder allowed. - Flexibility to adjust settings when working with non-typical materials

Unlike their previous filament extruder, the Composer Filament Maker allows the researchers to quickly adjust the temperature, diameter, fan, and extruder RPM settings. - All-in-one solution for production and experimentation

Besides improving their filament quality, the researchers are using the Composer Filament Maker to mix PCM with new plastics and to explore other innovative concepts in cooling system design. - High performance at an affordable price

With its superior filament quality, customization options, and affordable price, the Composer Filament Maker has proved to be an excellent value addition to the research facility.

More Success Stories

European Space Agency

How do researchers at ESA have the freedom to innovate – without wasting resources in the process.

Fontys University

How Fontys gained the ability to expand their polymer development studies – at a fraction of the cost.