Share this

Year and a Half Later - Setting the standard with PEEK

by 3devo on Jan 23, 2017 11:29:00 AM

Year and a Half Later – Setting the standard with PEEK

A year and a half ago, we began testing the prototype of what is today referred to as the Next 1.0 Advanced Level desktop filament extruder.

Taking forward the same commitment to quality and innovation, we focused on our next experiment – working with a semi-crystalline thermoplastic with mechanical and chemical properties ideal for sustaining high temperatures. This thermoplastic is known as PEEK (Polyether Ether Ketone).

Working with PEEK has presented interesting challenges, chief among which involved extruding it in the correct temperature range, while factoring in internal pressure, and without affecting the material’s crystallinity. It has been a good start, and our first trials turned out to be easier than expected.

But first, a bit about PEEK. And its key applications.

PEEK test result 1.75mm 3devo filament – done by Apium Additive Technologies GmbH.

PEEK finds its main uses in the Aerospace, Automotive and Medical industries.

Aerospace industry: Being strong, lightweight, and durable in a wide range of temperatures, PEEK is evolving into a popular choice of material in the aerospace industry. Its low price point does not hurt either.

Aerospace part

Source: www.roboze.com

Automotive industry: Besides the primary advantages of its high strength (safety), low weight, and durability in a wide range of temperatures, PEEK is also energy efficient and has the intrinsic ability to reduce vibrations. This makes it a perfect fit for the fast developing automotive industry.

Gear Pump

Source: https://apiumtec.com/en/3d-printer/

Medical industry: 3D printing has already established itself as an invaluable asset to the medical and dental industries, bringing a whole new level of freedom and accuracy to the process of printing unique parts and components. PEEK (or PEKK for dental industry) extends the scope of 3D printing, having similar properties as the human bone, and thus being one of the few materials that the body does not resist.

Implants

Source: www.pkm.kit.edu

Recent PEEK tests with the Next 1.0 Advanced Level desktop filament extruder

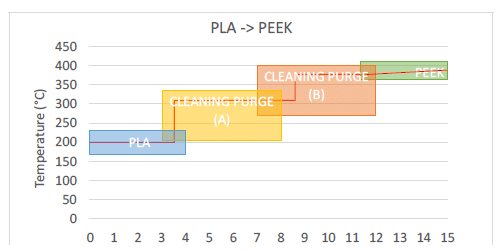

Switching from PLA to PEEK presented an unique challenge: building up the temperature inside the Advanced Level extruder to PEEK’s high melting point of 343 degrees.

We went about it in phases, using 2 cleaning compounds as transition materials. First, we slowly raised the temperature from 170 to 300 degrees with the first transition material. Once temperatures had crossed 300 degrees, we switched to the second transition material, and worked on reaching 390 degrees. This was the final stage in our trial, where we could proceed to extrude PEEK.

Because of PEEK’s steady flow and relatively quick cooling properties, extruding it to the desired thickness (2.85mm or 1.75mm) was easier than expected. Winding it on a spool was a different ballgame, though. Due to the strength of the material we had to tape the first part of the filament on the spool, so as to wind it correctly and prevent it from popping out of the spool.

3devo PEEK Filament 2.85mm

Transition materials and PEEK

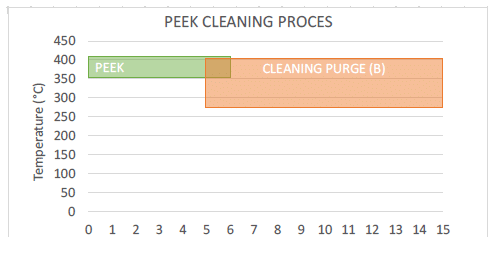

The transition material played a key role throughout our PEEK extrusion process. We first mixed the PEEK with the transition material, and then gradually lowered the temperature range while increasing the amount of transition material in the mix.

PEEK and purging compound @3devo

Phase 1

Image: 3devo BV – phase 1 extruding PEEK

Phase 2

Image: 3devo BV – phase 2 extruding PEEK

Extruding your own PEEK – The main advantages

Buying PEEK granulate will only set you back by around 100 Euros per kg, as opposed to a filament spool that will cost you to the tune of 1000 Euros per spool.

In addition to this, you can try creating custom composites with PEEK granules, by adding in different materials such as carbon fiber.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)