Filament Maker TWO

The most advanced filament extrusion system, made in The Netherlands.

Build custom materials, test new polymers, or close your filament loop — all from a single, compact, lab-ready system.

Create Custom Filament. Control Your Materials.

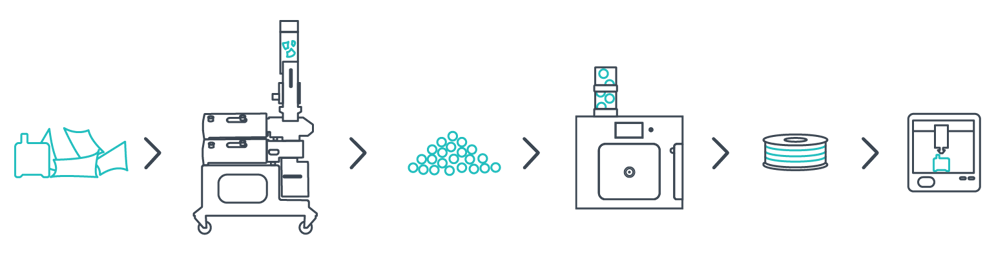

Shred it → Spool it → Print it

Designed For Professionals

Material R&D

Develop and test new polymer formulations in-house. Work with advanced composites like carbon or glass fiber, or validate materials like ABS, PETG, or PEEK.

Custom Filament Engineering

Create filament optimized for a specific function. Adjust properties, mix in additives or colorants, and fine-tune settings for functional prototyping and part validation.

Polymer Science Education

Bring real-world innovation into the classroom. Teach students about 3D printing, material science, and sustainability with tools designed for hands-on learning.

Recycle Plastic Waste

Close the loop in your R&D or production workflow. Repurpose support material, test prints, and process scrap into consistent input for future runs.

Hear From Our Customers

/3devo%20Logo%20Borderless%20-%20Dark%20Mode.png?width=200&height=64&name=3devo%20Logo%20Borderless%20-%20Dark%20Mode.png)