GP20 Plastic Shredder

The first step in your circular material development journey.

Reduce polymer waste into consistent, reusable granules.

Dutch-made and lab-ready, the 3devo GP20 Shredder empowers R&D teams to close the loop between testing, recycling and extrusion.

Key Features

High Precision

Swappable Blades

User Safety

Intuitive Design

Smart features, such as the intelligent feeding system, are powered by the machine's software.

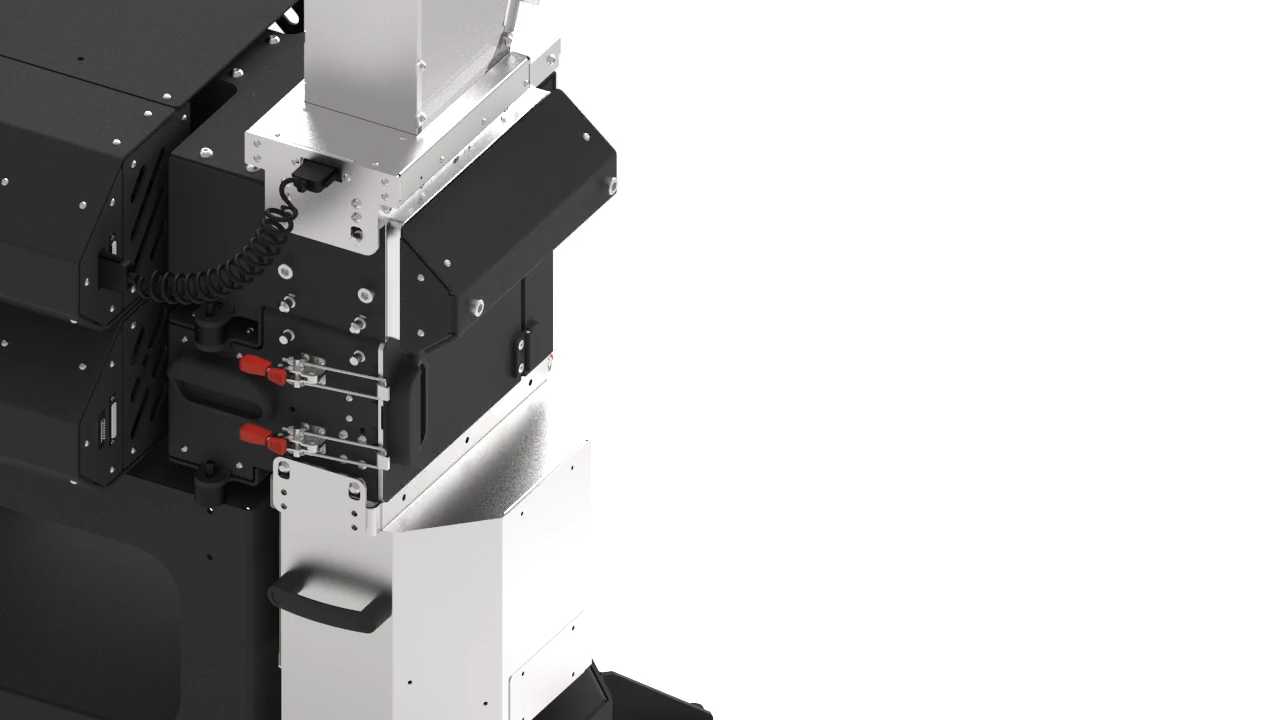

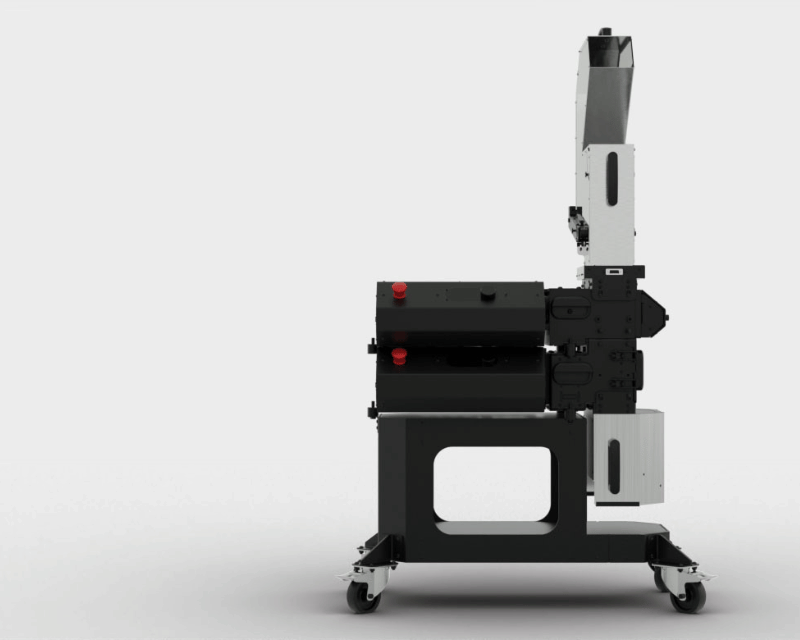

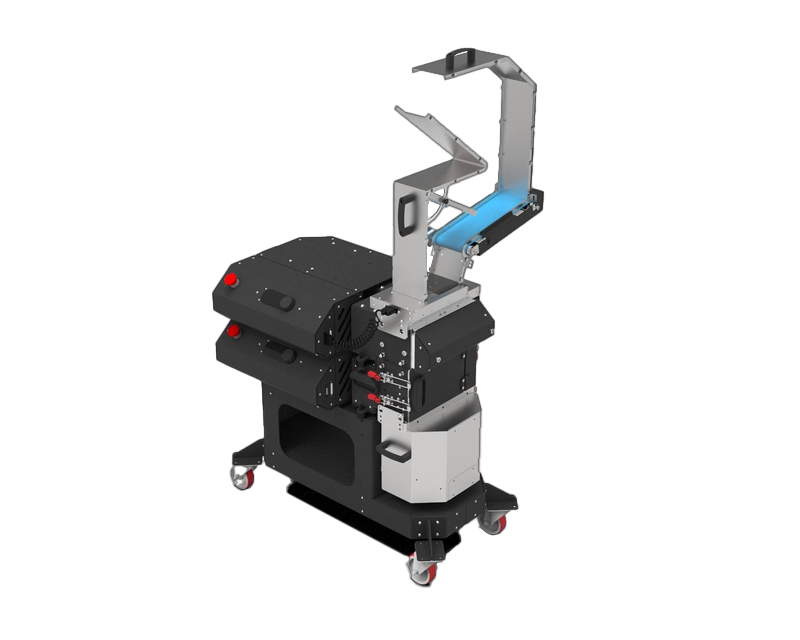

Design of the GP20 Plastic Shredder

GP20 Hopper

The hopper is precisely designed for efficient and safe operation. Its robust design allows for smooth feeding of a variety of thermoplastics, making it ideal for high volume shredding jobs.

The optimised shape of the hopper minimises the risk of clogging, ensuring a smooth flow of materials into the shredder.

In addition, the plastic shredder has an intelligent feed system that automatically adjusts the feed rate for optimum performance.

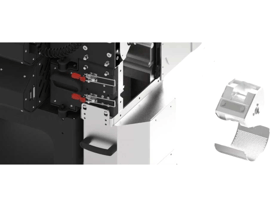

Shredder Unit

The shredder is engineered for precision and efficiency, making it an essential tool for recycling various thermoplastic materials. It features swappable blades with different numbers of teeth, allowing for efficient and effective cutting of plastics of various sizes.

With a total of 14 blades, the plastic shredder offers combinations of 2, 3, and 7 teeth blades to cater to specific shredding requirements.

Granulator Unit

The GP20 granulator is a highly efficient unit designed to grind plastic waste into uniform flakes. Featuring a 3-blade rotor and a 3.5mm filter screen, it ensures that the granulated material is of optimal size for filament production.

The blades provide consistent particle size, making the material ideal for further processing or direct reuse in the Filament Maker.

The granulator operates seamlessly with the shredder or as a standalone unit, offering flexibility and versatility in recycling operations.

GP20 Container

The container is designed to safely hold and transport crushed and granulated materials. Its design and easy-to-use locking mechanism ensures that materials are stored safely during processing.

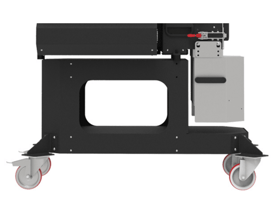

GP20 Trolley

The trolley is a convenient and mobile solution for transporting the shredder and the granulator unit. Designed with durable wheels and a sturdy frame, the trolley allows easy movement within your workspace.

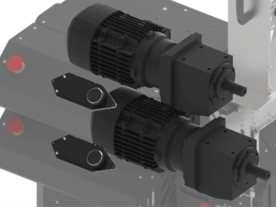

GP20 Motor

Both units are powered by two motors, each delivering 750 watts, for a combined total of 1500 watts.

One engine is dedicated to the shredder, while the other powers the granulator. This dual-engine configuration ensures that both units operate at optimal efficiency, providing consistent and reliable performance during brutal plastic recycling and production tasks.

Advanced Features

Dual Design

This dual design combines our intelligent plastic shredder with an integrated granulator, allowing you to focus on what you need. Recycling plastic of any shape and size into granulate-size 3D printing material. The functionality of the GP20 Plastic Shredder gives you the freedom and flexibility to incorporate it into any project within any industry.

Intelligent Settings

As the user, you can tailor the GP20’s settings specifically to your needs. The smart sensors work together to automate several manual operations:

- Smart Feeding: The material input belt automatically matches the processing speed of the GP20.

- Smart Troubleshooting: The knives can automatically reverse and continue to assure continuous processing.

- Smart Control: The temperature control sensor measures the processing temperature to eliminate material melting.

Different Blade Configurations

Enhance your GP20 Shredder's efficiency with our specialized blades. From light to heavy-duty tasks, choose the blade that fits your needs and achieve exceptional shredding performance:

- 2 Teeth Blades: Better grip for larger materials

- 3 Teeth Blades: Versatile Shredding

- 7 Teeth Blades: Heavy-duty shredding for tough materials

Compatible Materials

The GP20 Plastic Shredder is designed to handle a wide range of thermoplastics, making it suitable for a variety of recycling and manufacturing projects. Some of the materials you can use with the shredder:

PET

Commonly used in beverage bottles and food containers.

HDPE

Found in milk jugs, detergent bottles, and plastic bags.

PVC

Used in pipes, vinyl flooring, and medical equipment.

LDPE

Used in plastic bags, six-pack rings, and various containers.

PP

Found in packaging, textiles, and automotive parts.

PS

Used in disposable coffee cups and plastic food boxes.

PEEK

Used in aerospace, automotive, and medical applications.

Various plastics

Plastics like nylon, PC, and bioabsorbable materials.

Practical Applications

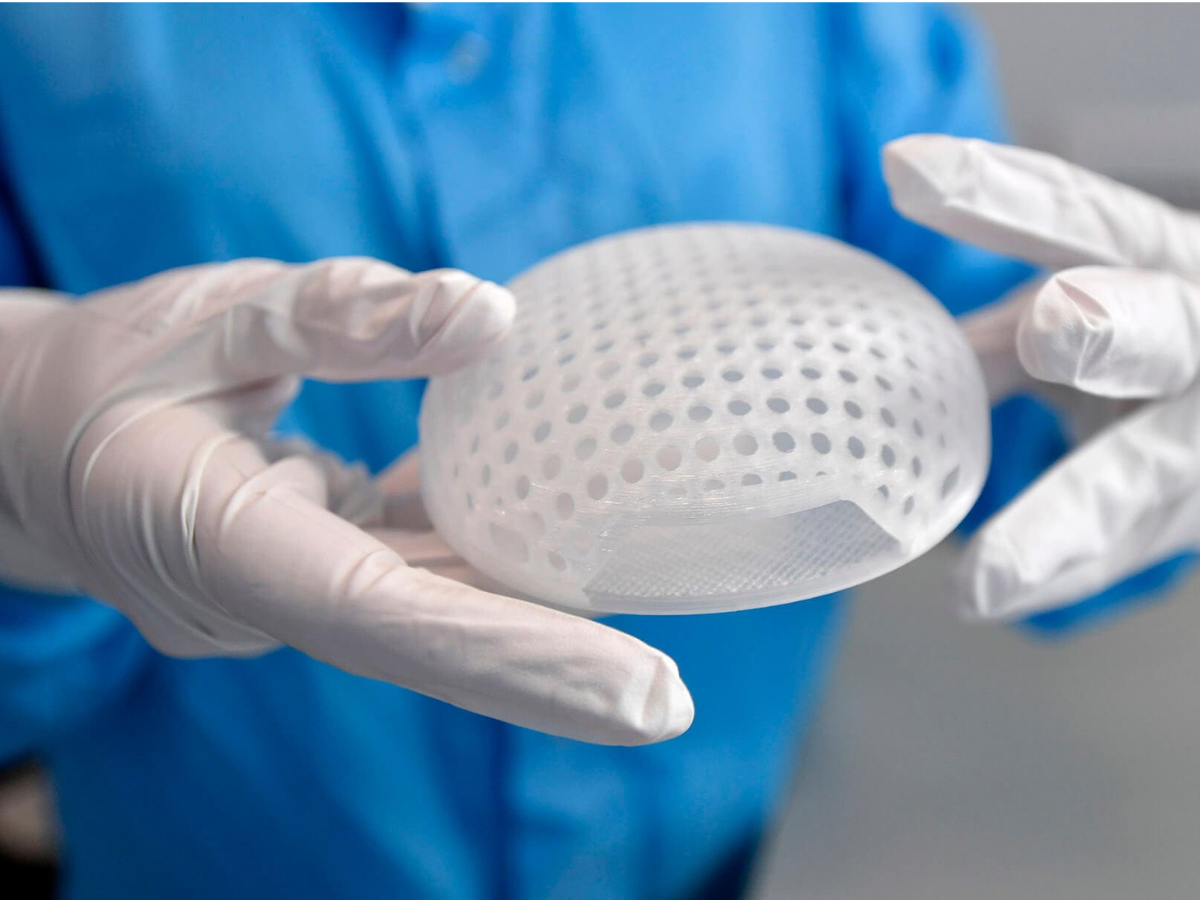

Lattice Medical Case Study

_compressed.png?width=3750&height=2813&name=GP20%20Product%20page%20pictures%20(10)_compressed.png)

Recycling Plastics Blog

_compressed.png?width=3750&height=2813&name=GP20%20Product%20page%20pictures%20(1)_compressed.png)

Explore More Case Studies

Specifications

AC 220-240V 50/60Hz

Your First Step Toward Circularity

The GP20 has become a go-to solution for innovators needing precise, small-batch plastic shredding. Whether you’re recycling waste prints or prepping materials for extrusion, this compact reclaimer delivers consistent results.

Ready to take control of your plastic processing? Let’s get started.

/3devo%20Logo%20Borderless%20-%20Dark%20Mode.png?width=200&height=64&name=3devo%20Logo%20Borderless%20-%20Dark%20Mode.png)