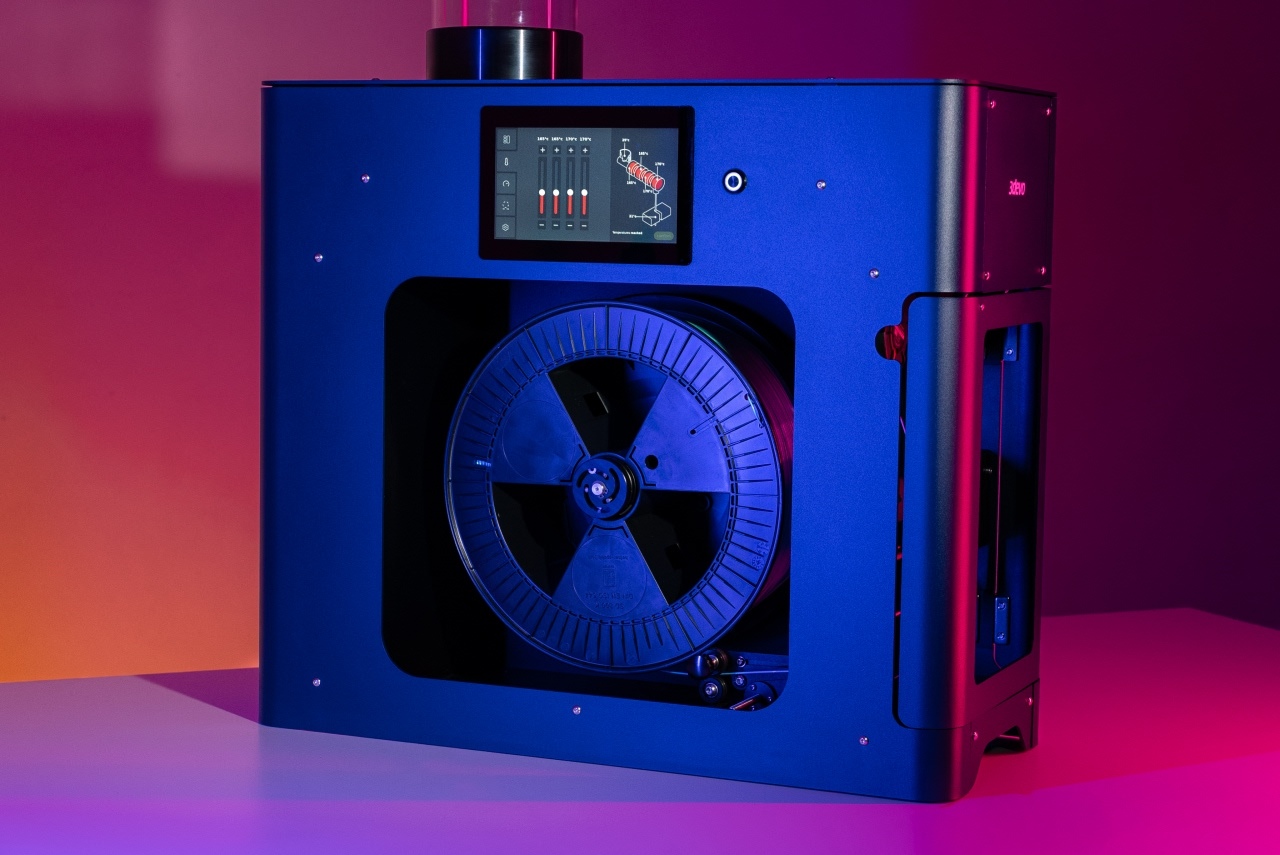

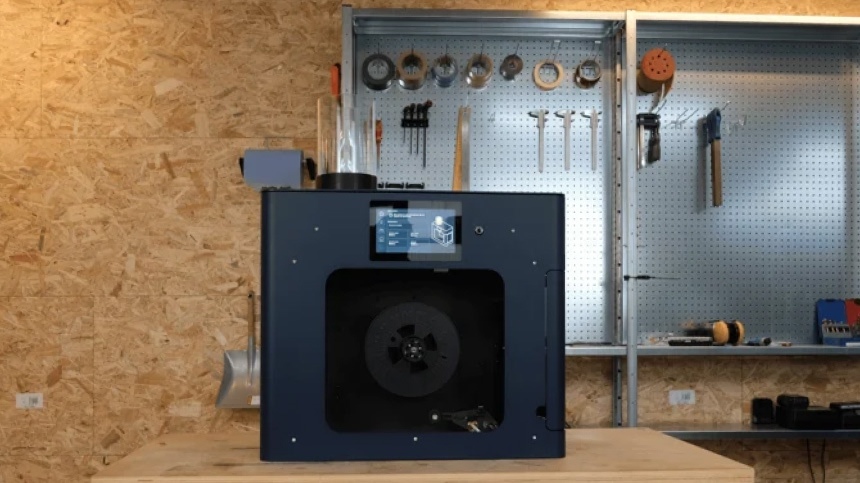

The core of our Dutch-made ecosystem for polymer development and circular innovation.

Develop, test, and recycle materials with lab-scale precision. Designed for researchers, engineers, and innovation teams advancing extrusion technology and material R&D.

Professional Polymer Extrusion for R&D

Key Features

Serviceability & Uptime

Optimization

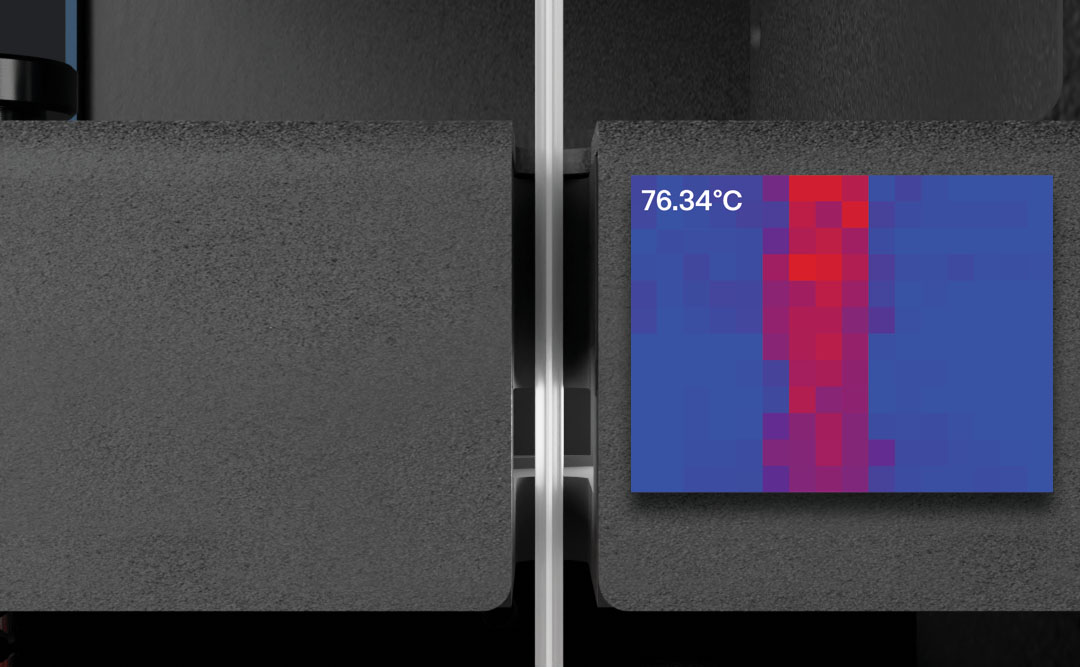

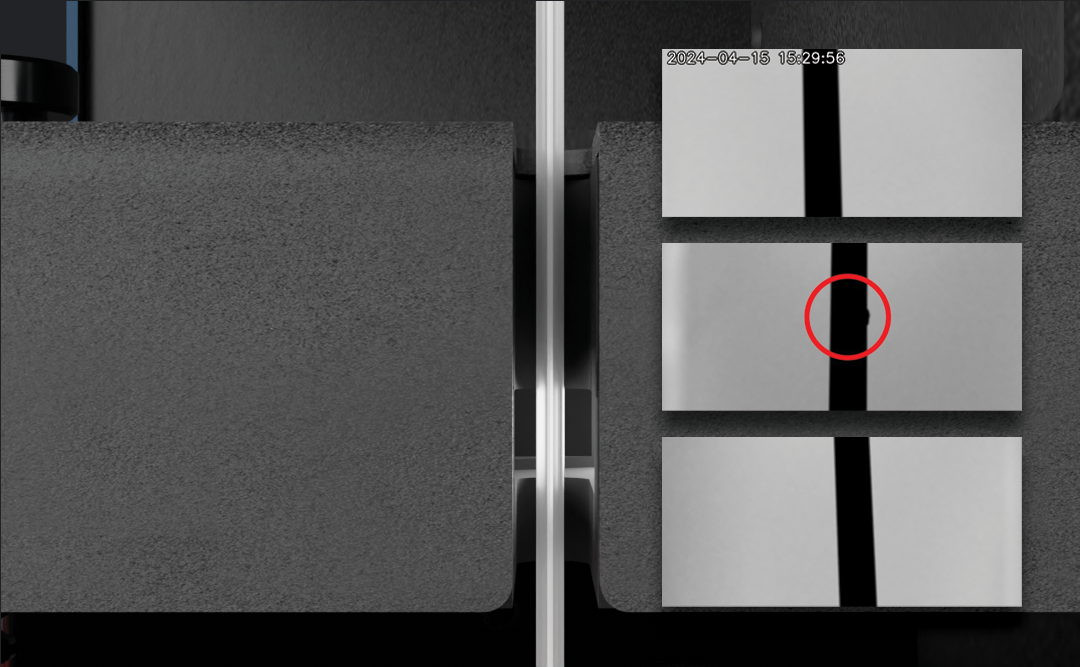

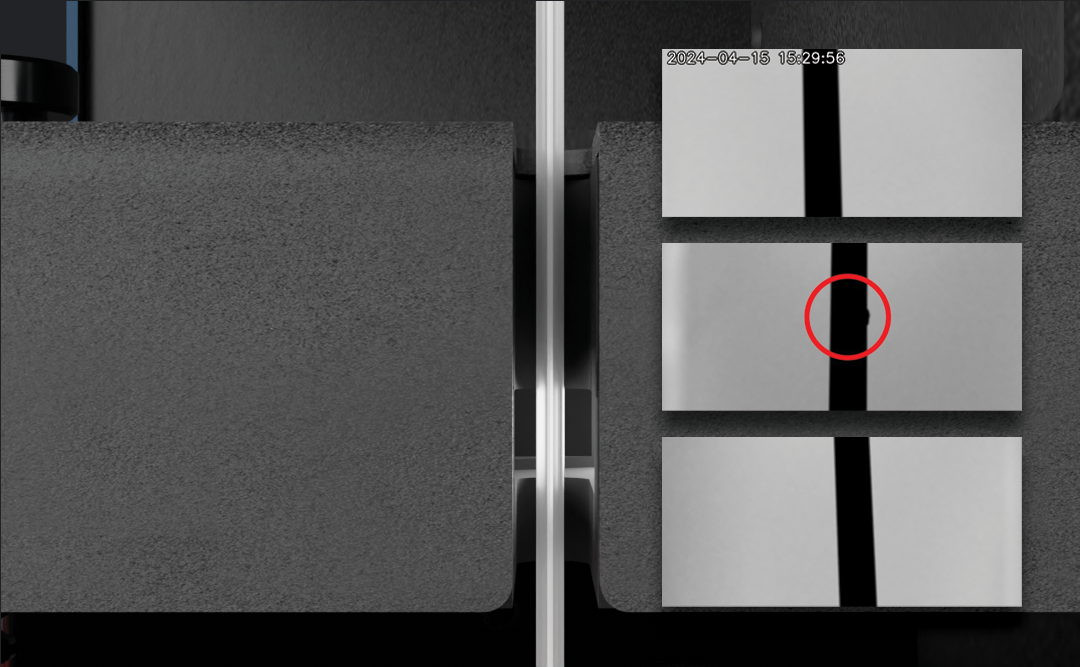

The machine’s split housing ensures internal access, allowing for:

- Quick screw removal for cleaning between tests and monitoring polymer melting, additive dispersion, or early degradation.

- Troubleshooting process issues

- Switching materials efficiently in R&D workflows

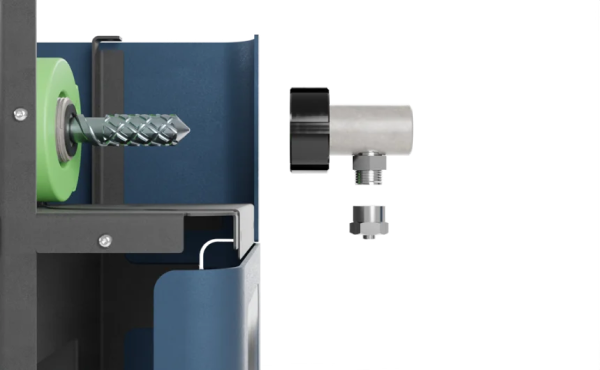

- Easy removal of the insulation sleeve, die head and nozzle

- Access to components for straightforward maintenance

Real-Time Extrusion

Metrics & Control

With advanced monitoring, you can validate hypotheses, detect trends, and export clean datasets - essential for high-stakes research:

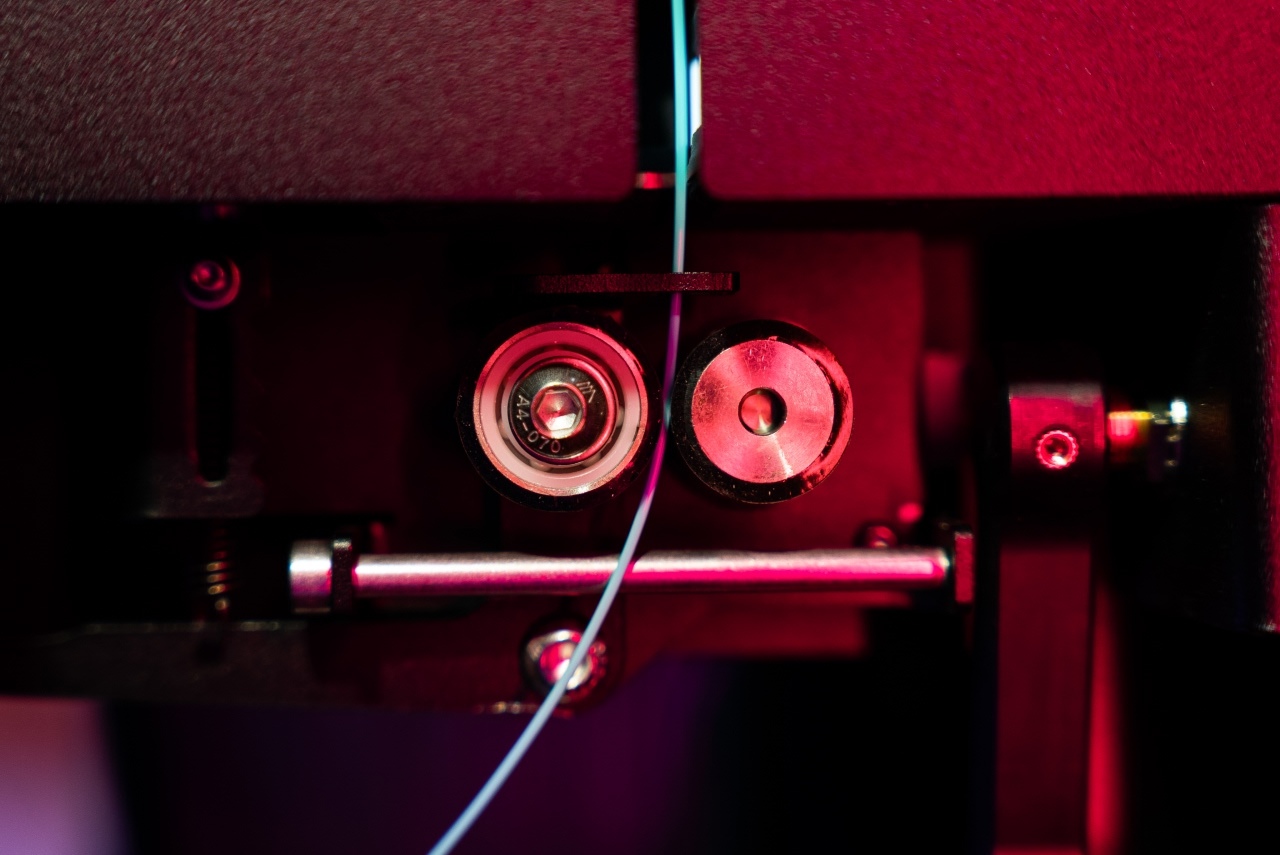

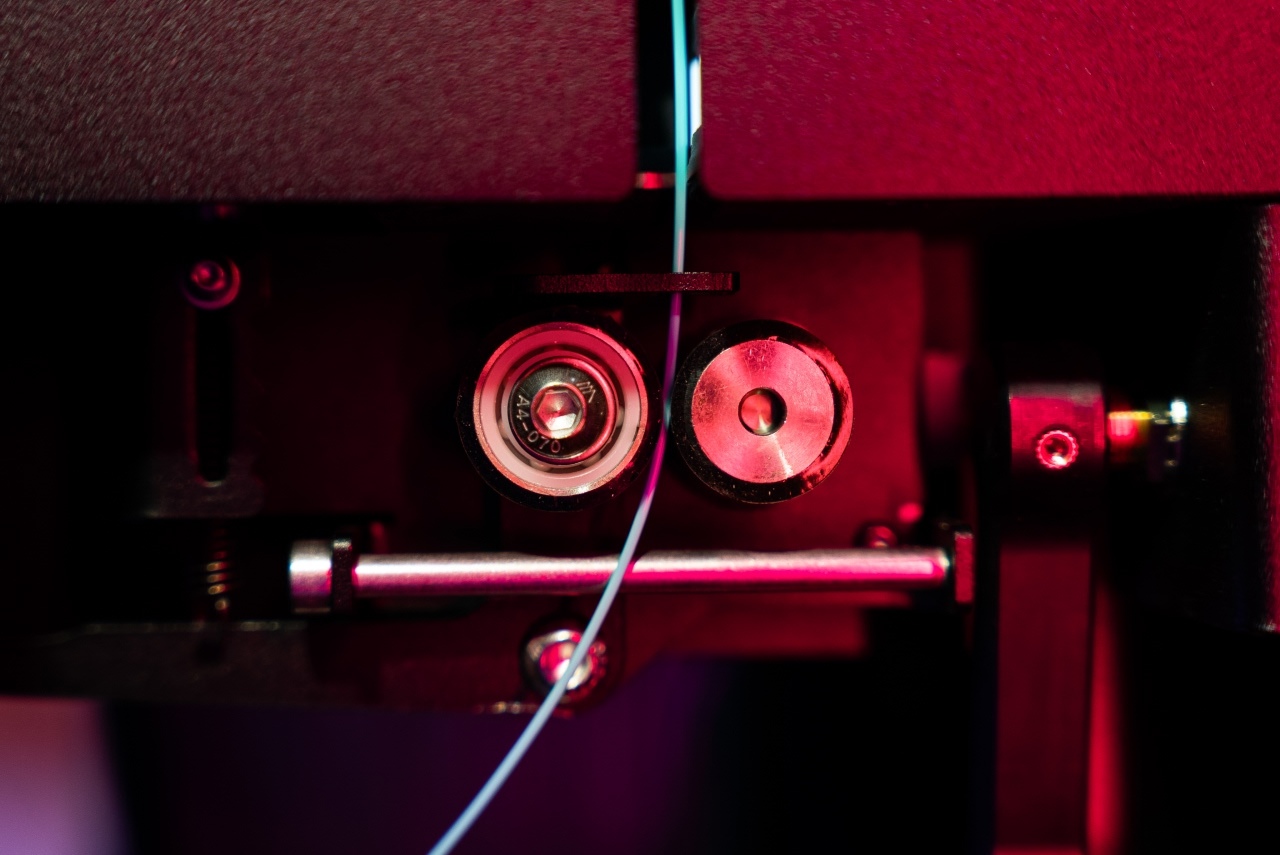

- High-speed 3-axis filament sensor (10μm resolution, > 25 measurements per second), measuring for filament ovality

- Real-time data logging + remote access, using the open-source InfluxDB software

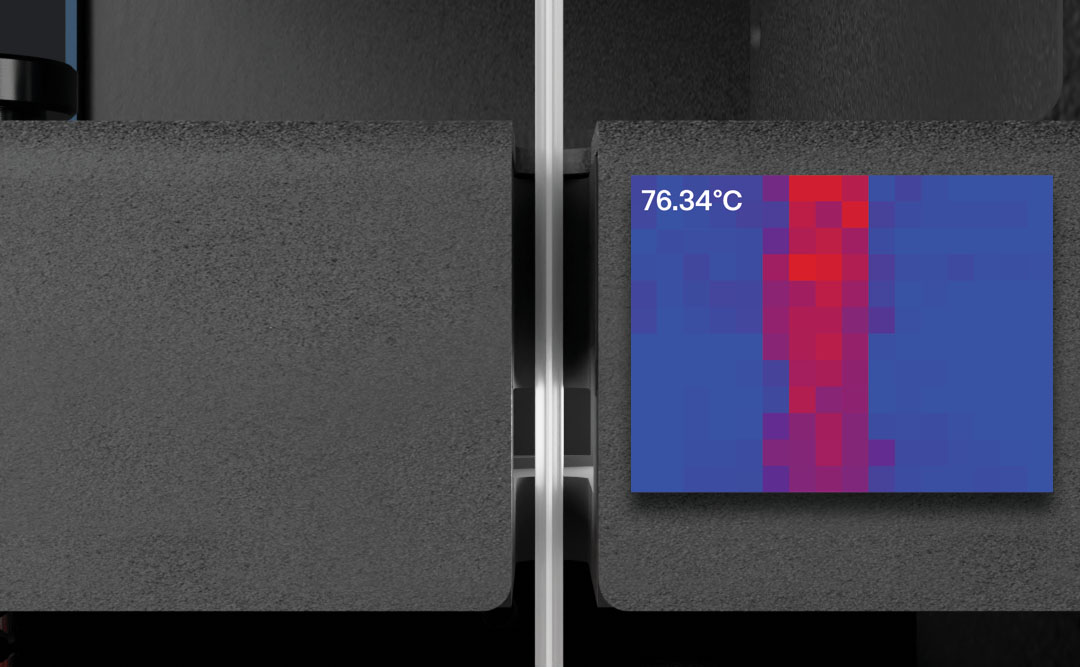

- Infrared thermal camera measuring the filament surface temp before it reaches the puller wheels, ensuring consistent filament quality, especially for high-temp materials

Available Soon: - Image processing capability, allowing for real-time monitoring of the filament's integrity, in order to identify and correct any imperfections

- Automatic spool fullness detection

Precision Control for

Reliable Material Testing

The Filament Maker TWO offers significant extrusion control advantages over its predecessor:

- Near-zero RPM fluctuation due to its more powerful extruder drive system (3x as much torque as the Filament Maker ONE)

- Extended screw (50mm longer than the Filament Maker ONE) for increased melt control (choose between mixing, precision or custom designed)

- Faster and more stable temperature control with more powerful heaters

- Cooled hopper with temperature monitoring

- Material and spooling presets, to instantly start extruding

Future-Proof

Technology & Customization

This isn’t just a closed-loop machine - it’s a platform. You can customize it according to your research needs, and also scale it with new modules or features in the future:

- Continuous firmware updates through an ethernet connection, based on user feedback

Available Soon:

- Open REST API for external control and data integration

- CAN bus connectors for custom attachments (mixers, feeders, etc.)

- Modular add-ons in co-operation with our R&D department

Streamlined

Control and Setup

Whether you’re adjusting parameters on the fly or logging data for later analysis, its improved user experience is there to keep your research moving forward, not slow it down:

- Touchscreen interface with easily accessible settings, parameter controls, and real-time on-screen notifications

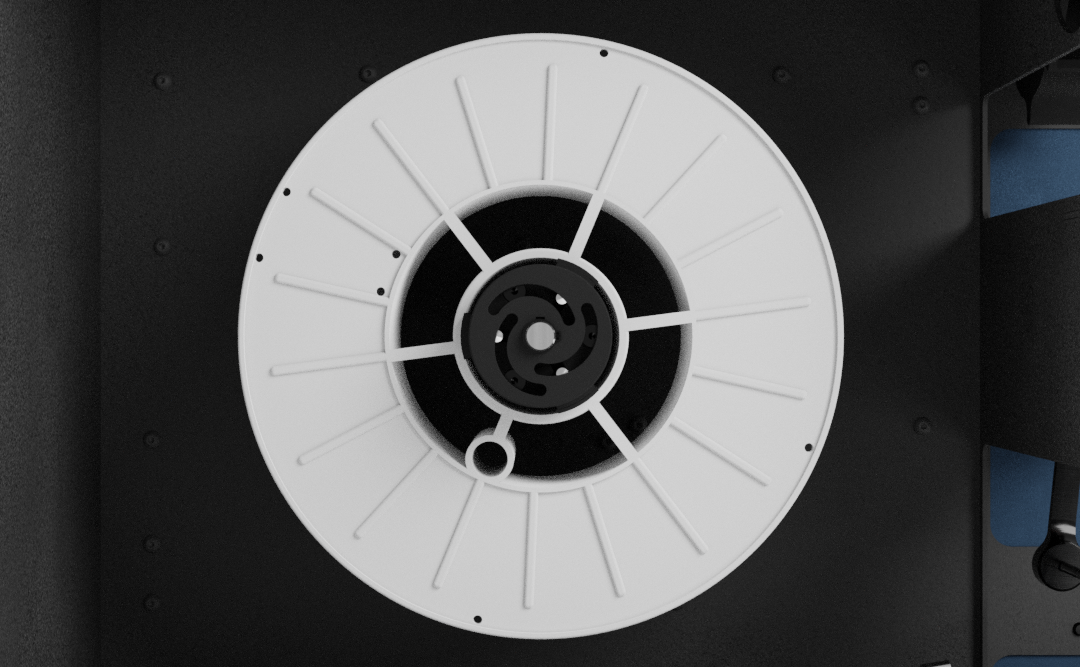

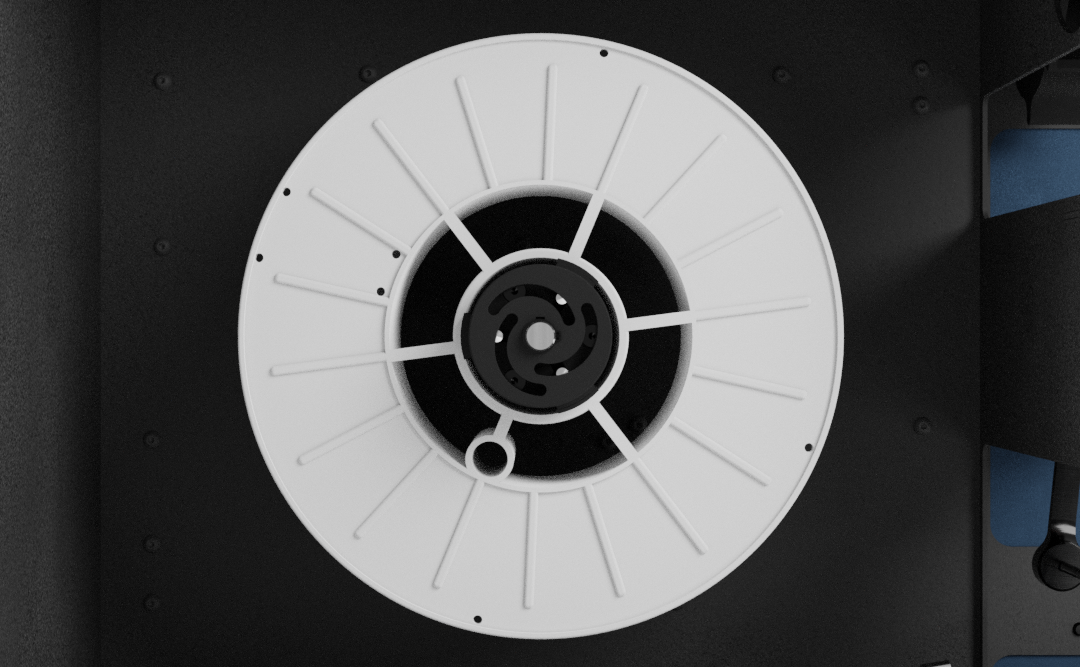

- Variable puller tension to accommodate different materials, ensuring

optimal tension across both flexible and rigid materials - Spool chuck design to make loading simple and reduce setup time

- Up to 3kg spool capacity

Compatible Polymers

The Filament Maker TWO is engineered for advanced polymer research and development, capable of processing a wide range of thermoplastics with precision. Its use cases include material validation, formulation testing, and recycling across various polymer types.

Common waste to recycle

| PET | PLA | PP | HDPE |

| PETG | ABS | PS | LDPE |

| PC | PHB |

Engineering polymers

| TPU | POM | PA6 | PVA |

| TPE | PCL | PA66 | PA |

| ASA | PA12 |

High performance polymers

| PEEK | PEI | PSU |

| PEKK | PPSU |

Additives and composites

Specifications

Weight

42 kg

Max. RPM

0 – 15 RPM

Active cooled

Yes

Heating zones

Heater power

4

230W per zone

Hardening treatment

Compression

Screw Design

Compression Ratio

L/D ratio

Nitrided

3 stages

Interchangeable

2,25

17,75

Framerate

Measurements

Measurements axis

Thermal sensor

5 fps

> 25 per second

3

Yes

High Temp Nonstick Max.

Puller Tensioner

380 °C

Adjustable

Spool Inner diameter

Max. Spool width

Max. Spool weight

Automatic tensioner

Friction wheel

Spooling system

49 mm - 55 mm

100 mm

3 kg

Yes

Yes

Self tightening spool holder

Consumption Max.

Voltage

Frequency

1300 W

230 V or 110 V

50 – 60 Hz

Networking

Power plug

USB

Ethernet

Schuko male to C13

USB - B

Step Up to the Next Generation

Explore how the Filament Maker TWO can take your material development to the next level. Whether you’re upgrading from the ONE or starting fresh, our Material Specialists are here to guide you.

/3devo%20Logo%20Borderless%20-%20Dark%20Mode.png?width=200&height=64&name=3devo%20Logo%20Borderless%20-%20Dark%20Mode.png)