Real-World Polymer Innovation

See how researchers, engineers, and industry leaders use the 3devo ecosystem to turn material ideas into tangible results.

From recycling experiments to advanced extrusion and circular R&D, these stories showcase impact in action.

Let's Talk About Your Project

FAQ

How are the subjects for your case studies selected?

Our case study subjects are chosen based on a combination of factors. We prioritize innovative applications of our products, unique challenges faced and overcome by users, and significant contributions to the 3D printing and material development community. Additionally, feedback from our customers and the broader community plays a pivotal role in guiding our selection. Our goal is to highlight diverse experiences and solutions, providing insights and learnings that can benefit everyone in the industry.

Our case studies cover multiple industries, and we keep adding new case studies occasionally. This means that we try to cover as many industries as possible. Here is a list of industries we currently cover in our case studies:

- Healthcare & Medical Technology: Lattice Medical showcases the use of patented 3D technology, Lattice, to revolutionize breast reconstruction and medical implants.

- Education:

1. Fontys University demonstrates the application of 3devo's technologies in researching and producing bioplastics from food waste.

2. Lapland University of Applied Sciences emphasizes recycling and sustainable practices in their 3D printing lab, focusing on the concept of a circular economy.

3. Embry-Riddle Aeronautical University delves into the realm of battery cooling systems, working on creating self-contained, 3D printable heat sinks using phase-change materials. - Construction & Material Development: As highlighted by the Sika case, which focuses on advanced construction solutions and material development.

- Automotive Manufacturing & Sustainability: The Audi case showcases recycling initiatives and sustainable practices in the automotive manufacturing sector.

- Aerospace & Space Exploration:

1. Embry-Riddle Aeronautical University is engaged in ground-breaking research on heat regulation systems, particularly the development of 3D printable heat sinks.

2. The European Space Agency (ESA) works on developing materials and technologies for future spaceflight applications, exploring the potential of in-space manufacturing and recycling using 3D printing.

These diverse case studies demonstrate the wide-ranging applications of 3devo's technologies across various sectors and the innovative ways in which different industries address unique challenges and bolster their operational efficiencies.

These case studies provide detailed examples of how diverse industries have adopted 3devo's cutting-edge technologies. By diving into these real-world applications, professionals can derive actionable insights to better inform their strategies. Whether you aim to experiment with your own 3D printing materials or unlock new avenues in recycling, our case studies can be a starting point. Specifically, we offer:

- Guidance on harnessing the potential of Filament Makers like the Composer and Precision Series for material research and development.

- Insights into the transformative power of the GP20 Shredder Hybrid in the recycling journey.

- Understand how the Airid Polymer Dryer is pivotal in ensuring quality 3D printing filament by eliminating moisture complications in polymers.

Our case studies provide a comprehensive glimpse into how 3devo solutions seamlessly blend research, innovation, and sustainability.

Absolutely! We always welcome professionals and organizations that have utilized our products to share their experiences and outcomes. If you're interested in collaborating on a case study, please contact our sales team. Fill out your information, and in the dropdown, click "other". We'll guide you through the process, ensuring your story and insights reach a wider audience and help advance the 3D printing community. Your contributions can provide invaluable lessons and inspiration to others.

Our latest innovations

Read about our latest innovations in our blogs below. Everything from Case studies, 3D Printing Innovations to Recycling plastic waste.

Formnext 2025 Recap: Materials, Workflows & Real Insights

From Waste to Filament: Experience 3devo’s Dutch-Made Ecosystem at Formnext 2025

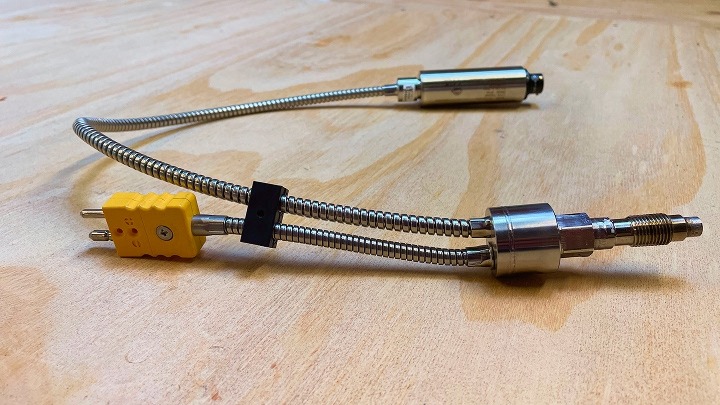

How We're Developing a Pressure Sensor for the Extrusion Process