Share this

When Do I Start Spooling Filament

by 3devo on Aug 17, 2021 10:16:00 AM

You’ve just spooled your filament, and you’re ready to put it in your 3D printer. But you notice something isn’t looking right, and your filament is in bad shape. Now you realize you’ve wasted your time and have to start the extrusion and spooling process all over again.

But at least this time, you have this guide that takes you along the process of telling when your filament is ready to be spooled and why you want to make sure you spool correctly!

With different filament makers on the market, the guidelines to follow may vary; we’ve curated the following tips based on our experience with our filament makers.

Let’s get to it.

How can I tell when my filament is ready to be spooled?

Well, when your filament is of good quality.

That answer may seem obvious, but in other words, there’s no point spooling your filament during the “research” phase when you’re still trying to find the best settings. So instead, you’ll have to find these settings without spooling. Finding these settings means three things:

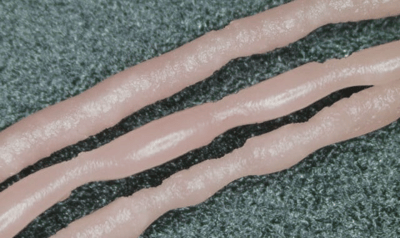

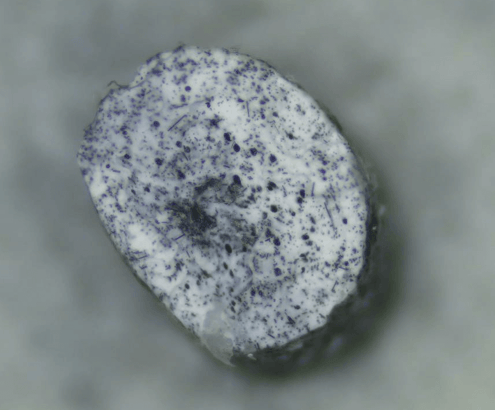

1. The filament must look good to the naked eye (no bubbles, no burnt particles, no surface defects, and a homogenous color),

2. The filament must be round. The sensor in our filament makers measures in one direction only, so you can check the roundness by either rolling it between your fingers (may take some practice) or an even easier way, by using a caliper,

3. The diameter fluctuation (the tolerance) must be tight enough; this is hard to see with the naked eye, so we suggest using the Filament Thickness graph on DevoVision. The tolerance must remain stable, within an acceptable range for at least 20-30mins. The optimal tolerance is typically +/-50 microns, but this is arbitrary. The ideal tolerance depends on your 3D printer configuration. Often, 3D printers can work with a tolerance of +/-100 or even +/-150 microns.

Resetting Spool Settings after a Change

So you’ve just swapped out your full spool for an empty one, you’ve reattached your filament and notice that the rotation is quite slow. The reason for this is because the spooling speed is based on the dimensions of the filament and how fast it’s being extruded.

The fuller the spool gets, the slower it will run. It’s crucial to restart the spooling process and go through the spooling wizard so that the right tension is found and your filament is spooled properly.

What’ll happen if I don’t spool correctly?

Excessive tension can deform the filament and disturb sensor readings, meaning that your final thickness would end up thinner than expected. And insufficient tension leads to entanglements within your spool. And loose or entangled spools are basically unprintable, which would eventually lead you to have failed 3D prints.

Your spools will not always be 100% neat, and we know that, but you must get as close as possible to that. For example, if you started spooling when your filament’s thickness was still unstable, you’d notice that your 3D prints will fail quite suddenly or be inaccurate.

There you have it! How to check if your filament is ready to be spooled, and why you want to make sure you spool it correctly! Remember to store your filament properly once you’ve spooled so it remains in perfect condition for your 3D print!

Are you having challenges with finding the right settings to get the best results? Check out our support platform filled with support guides, tutorials, and more!

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)