Share this

Plastic Pigments - The Complete Guide on How Colorants Work

by 3devo on Sep 4, 2023 10:00:00 AM

.jpg?width=3264&height=1540&name=MicrosoftTeams-image%20(44).jpg)

Introduction

In the field of Fused Deposition Modeling (FDM) 3D printing, the scope for innovation is virtually limitless. The array of available thermoplastics is large, encompassing materials such as PLA, ABS, TPU, PA6, and PEEK, among others. Each of these materials exists in many forms, specifications, and grades, offering multiple options for various applications.

While 3D-printed objects often fulfill roles in rapid prototyping and functional applications, the potential for customization extends beyond mere form and function. Indeed, the aesthetic aspect—particularly color—plays a critical role in differentiating products. This article explores the nuanced subject of filament customization, with a particular emphasis on the employment of masterbatches to imbue 3D-printing filaments with vibrant and enduring colors.

What Are Pigment Colorants Anyway?

Pigment colorants play a crucial role in determining the appearance and quality of 3D-printed objects. These colorants are added to the base polymer material to give it a specific hue. Unlike dyes, which dissolve into the material, pigments are insoluble particles that are mixed into the polymer matrix.

The addition of pigments occurs in minimal proportions, yet the impact on the filament's color is significant. One key advantage of pigments is their resistance to various environmental factors, such as light and heat, which contribute to the long-term stability of the product's color. The inert nature of pigments also ensures that they do not interfere with the chemical structure of the polymer, thus maintaining the material's inherent properties. This makes pigments a preferred choice for applications that require both aesthetic appeal and functional integrity.

In summary, pigment colorants are essential in 3D printing, offering both vibrant colors and durability without compromising the material's structural integrity.

Understanding Masterbatches

What Are Masterbatches?

A polymer masterbatch is a concentrated mixture composed of a base polymer and various additives or agents, such as pigments, fillers, stabilizers, and other processing aids that you want to infuse into your base polymer.

Let’s assume your base polymer is ABS. However, the masterbatch would also be made of ABS, containing a certain concentration of additives. Typically, 2% of the masterbatch is enough to modify the properties of the full batch. We can see it like this: 98% of virgin ABS + 2% of ABS masterbatch = 100% of enhanced ABS. Masterbatches are polymer-specific – an ABS masterbatch cannot be blended into PLA filament.

How Do Masterbatches Work?

These masterbatches serve as convenient and efficient methods for incorporating specific properties, colors, or functionalities into polymers during manufacturing. Masterbatches are typically produced via a compounding process, during which the additives are thoroughly mixed and dispersed within the polymer matrix, resulting in a homogenous blend that can be easily incorporated into end products. A small pouch of masterbatch pellets at a lab scale will help you enhance several kilograms of polymer. Masterbatches come with speed and freedom of experimentation.

The Focus on Pigment Masterbatches

Characteristics

In the case of pigment masterbatch, the additive in focus is pigment. Pigments are finely ground, colored particles that are inert in the polymer matrix, meaning that the pigment is to be dispersed into the base polymer without reacting chemically. This characteristic is pivotal, as it enables the pigments to maintain their color integrity while weaving seamlessly into the filament's structure.

The Role of the Carrier

Pigment masterbatches are precisely formulated mixtures containing a high concentration of pigment dispersed within a compatible polymer carrier. Said carrier acts as a medium for the pigments and facilitates their uniform dispersion within the polymer melt, ensuring consistent and even coloration throughout the final product. By melting inside the extruder, the carrier will release the pigment into the whole matrix, resulting in colored filament.

Why not use pure pigment?

Pigments are colorful substances ground into very fine powder. Adding pure pigment powder to virgin polymer is possible but challenging. The challenges are:

- Dosing the right proportion of polymer vs pigment

- Feeding particles of different shapes into one system homogeneously. Including fine powder, which is also difficult to handle

- Mixing homogeneously once the plastic melts

Certain twin-screw extruders are specialized in such mixing but are not suited for filament making. Sequencing the process into 2 steps is the easiest strategy:

- Pre-compounding the plastic and pigment into masterbatch pellets. Or buying the masterbatch pre-made 😉

- Extruding the plastic and masterbatch, both in pellet form, with a single-screw extruder

In other words, masterbatches allow you to bypass the pigment addition step and make filament immediately with a single screw extruder.

Inks are similar to masterbatches in the sense that they consist of a medium (water) containing a concentration of pigment. Ink cannot be poured into an extruder since water damages the extrusion process, disturbing the melting process and forming bubbles in the final filament. Other media, like oil, are also incompatible with extrusion since they disrupt friction.

.jpg?width=533&height=400&name=MicrosoftTeams-image%20(51).jpg)

Masterbatches in Action

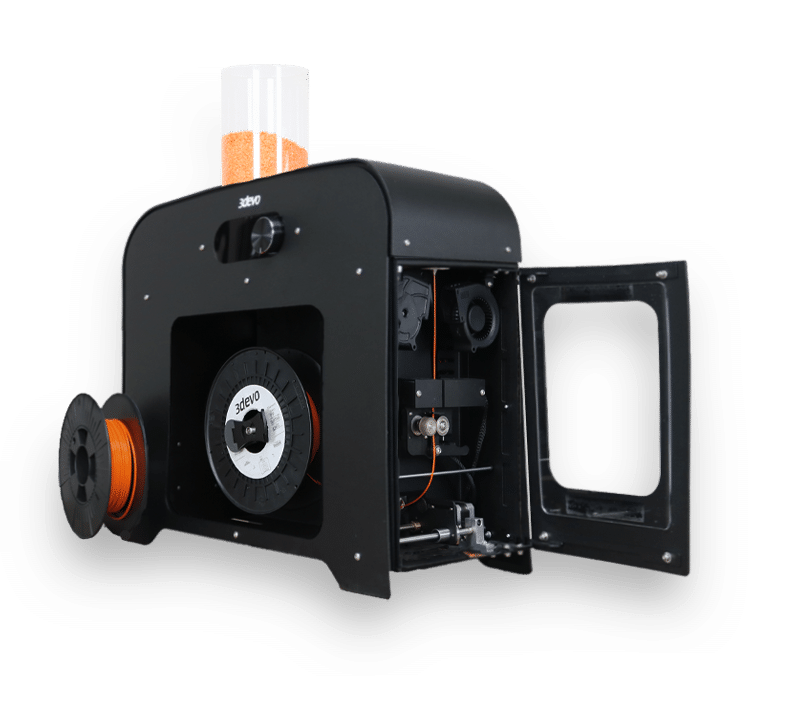

Inside the Extruder

The process of filament extrusion can be divided into 3 phases :

- Input: Feeding in the hopper

- Core: Melting and pushing inside the barrel

- Output: Cooling down and spooling

Let’s walk through the process, focusing on what happens to the colorful masterbatch pellets.

.png?width=781&height=500&name=MicrosoftTeams-image%20(55).png)

Input: feeding in the hopper

As explained above, feeding powders can be challenging, but feeding a pellets+pellets mix is easy. In most cases, 98%wt of the pellets will correspond to virgin polymer, while the remaining 2% will be masterbatch. Because the rest of the process can act as a buffer, there is a tiny bit of room for heterogeneity. Mixing the masterbatch and carrier thoroughly in a jar and feeding the mixed input should result in sufficient homogeneity.

Core: Melting and pushing inside the barrel

This section can be divided into 3 phases. Each phase corresponds to a third of the barrel length and to a state of the matter:- Feeding zone, the material is still solid, being grabbed by the screw from the hopper and pushing the rest of the material.

- In the transition/compression zone, the material gradually melts from solid to liquid. When the masterbatch is compatible with the carrier, both types of pellets should be melting at the same time. The same settings (screw speed, temperatures) will be applied to both the carrier and the masterbatch, so they need to have a similar melting behavior.

- Metering zone a the melting having already occurred, the liquid blend is being pushed forward. This is also the best place to include a mixing screw tip which will induce great turbulence in the flow, ensuring maximum mixing. Homogeneous results can be achieved with different screw geometries, but a mixing tip is recommended.

Output: Cooling down and spooling

The homogeneously colored filament should be coming out of the nozzle now. It shouldn’t behave much differently from virgin filament. This phase of the extrusion process allows us to tell whether the masterbatch grade is compatible with the polymer grade: numerous bumps on the filament surface indicate a severe melting issue- most likely that the masterbatch is not fully melting. In such ‘bad’ cases, troubleshooting might be possible by adjusting the settings. Otherwise, another masterbatch grade must be tested.

The Importance of Screw Design

The filament extrusion process relies on feeding, melting, pushing, and then obtaining filament. The mixing happens more or less throughout the whole process since extrusion relies on the rotation of a screw, causing a lot of friction. Melting can be ensured by choosing a masterbatch that is compatible with the carrier and by selecting appropriate settings (mainly screw speed and temperature profile). Some mixing happens in the early stages of the process, but especially at one crucial moment.

Mixing liquids is a lot more efficient than mixing solids in terms of homogeneity. Plastic is liquid in the last zone of the barrel–metering zone; as explained above, the tip of the screw is the main point of focus.

Traditional single-screw extruders are equipped with ‘smooth’ screw tips, perfectly designed for stability. Some extruders are designed with a special mixing screw tip. Different types of mixing tips exist, though all of them aim at the same effect: generate turbulence to mix the liquid flow.

What Could Go Wrong?

The Risk of Incompatibility

Mainly one thing: incompatibility. Incompatibility between the masterbatch and base polymer.

It will often take the form of melting issues during filament extrusion. Typically, big bumps are visible on the filament surface, corresponding to unmelted particles. Some masterbatch pellets might be melting only partially or not at all. When monitoring extrusion data, you might also be able to spot instabilities in the motor behavior, overall flow speed, and of course, filament thickness.

Implications for 3D Printing

This is a severe issue, especially when undetected and especially when it comes to 3D printing. Classic printheads being equipped with a 0.4mm nozzle, they would clog easily when a huge 1mm inconsistency will try to pass through. The goal of extrusion is to result in a very smooth filament, stable in tolerance and homogeneous in composition.

Reasons Behind Lack of Melting

The lack of melting can be due to inappropriate settings that do not allow the masterbatch to melt. For example, insufficient temperature or insufficient friction. Or perhaps the carrier melts properly on its own but is just incompatible with the masterbatch.

Solutions for Melting Issues

In order to favor melting, there are two options, mainly: increasing the temperatures to provide more conductive heat to the barrel or reducing the temperatures while increasing the screw speed. The second option is a bit counter-intuitive but is a fun example of how extrusion works. Reducing extrusion temperatures and increasing the screw speed will generate more friction inside the barrel, ultimately resulting in more heat and better melting.

Variability Among Masterbatches

Not all masterbatches are equal. Each brand is different, and so is each color. There are obviously differences between brands and suppliers, but there is more. Each individual pigment is a substance that gives color but can also alter the mechanical or melting behavior significantly.

The Case of White Masterbatch

For example, white pigment often consists of titanium dioxide and is notoriously difficult to melt. White masterbatch, therefore, often causes unmelting issues.

Masterbatch Compatibility with Specific Materials

In other words, your ABS might be compatible with the green masterbatch from a given supplier but not with the black one, just as an example.

The Importance of Compatibility Testing

It’s about finding a trusted base carrier and a high-quality masterbatch and then running a compatibility test. Once you find both as well as optimal filament making parameters, extruding colorful filament will be a breeze.

Limitations in Mass Production Repeatability

The final limitation is long-term instability or mass production repeatability. Because feeding masterbatch pellets + carrier pellets into a single-screw lab-scale extruder is technically not as accurate in the long run as a dedicated industrial installation running 24/7 for weeks or months, one might detect slight differences between several spools produced at different moments.

Subtle Color Gradient Issues

The color gradient will most likely not be visible to the naked eye but might exist. This is the little drawback that comes with great process speed and agility.

.jpg?width=533&height=400&name=MicrosoftTeams-image%20(46).jpg)

Environmental Impact of Pigments

When it comes to pigment selection, one factor often overlooked is the environmental impact. As we collectively gravitate towards sustainability, considering the eco-friendliness of pigments becomes crucial. Some pigments, especially older formulations using heavy metals like cadmium, can be detrimental to the environment. Therefore, opting for pigments free from toxic substances makes your filament more marketable and contributes to responsible manufacturing. This is especially pertinent given the rising interest in sustainable materials, a topic many competitors don't address.

The Fun Aspect: Chromatic Experimentation

Masterbatches are easy to use while still giving the user great freedom to experiment and explore. For example, adjusting the masterbatch dose finely can help you create translucent filament: colorful but still transparent. For example, when the manufacturer recommends 2-4%wt, 0.5% or 1% might do the trick.

There is always a saturation threshold. There is no need to throw in 20% of masterbatch – saturation will probably cap at 4%, and 20% might cause severe melting issues.

‘Rainbow’ or multicolored filament can be created by preparing multiple small batches of various colors and then feeding them one after the other in the Filament Maker. There is a certain inertia to the process. Since extrusion relies on continuous mixing, transitions between batches are never instantaneous. However, this can result in multiple colors on the same spool or a gradient of a single color.

.jpg?width=533&height=400&name=MicrosoftTeams-image%20(43).jpg)

Conclusion

In conclusion, the use of masterbatches to infuse captivating colors into 3D printing filaments offers a realm of creativity and personalization. These concentrated mixtures, containing base polymers and additives, seamlessly introduce specific properties and colors during manufacturing. Pigment masterbatches, especially, play a vital role by dispersing finely ground pigments uniformly within the filament, resulting in consistent and appealing colors.

During filament extrusion, careful settings and mixing screw tips ensure proper melting and mixing, although challenges of incompatibility can lead to melting issues. Despite these challenges, masterbatch-based filament personalization allows for experimentation in creating translucent filaments or multicolored gradients.

The journey of infusing color into filaments celebrates both technical prowess and creative imagination. The art of giving color to 3D printing filament, facilitated by masterbatches, harmonizes science and creativity, offering endless possibilities for users to express their visions vividly.

Why not go even further? Let’s look at the whole bright picture and the many doors unlocked by the process of Filament Making. One can now process custom exotic polymers that maybe don’t exist in filament form on the market. Enhance filament with functional additives (carbon fiber, eggshell…). And give it a color just as special as its properties and recycle it.

FAQ

Colorants are substances used to impart color to materials like plastics. In 3D printing, colorants can be added to the raw plastic material to produce colored filaments. They typically come in different forms like powders, liquids, or masterbatches.

Generally, our Filament Maker is compatible with a variety of colorants, including powders, liquids, and masterbatches. However, compatibility might differ depending on the type of plastic you're working with.

When choosing a colorant for your plastic, always consider the type of plastic you're using. High-temp plastics like ABS need colorants that can withstand those conditions, while lower-temp plastics like PLA have different requirements. Consult the technical data sheets that come with your colorants for compatibility info, or better yet, chat with the manufacturer for expert advice.

Running small-batch tests is also a smart move. It helps you understand how the colorant behaves during filament creation and lets you experiment before scaling up.

In a nutshell, not all colorants work well with all plastics, so take the time to find your perfect match. Whether you're following guidelines or getting experimental, proper pairing can make your 3D-printing project pop!

Yes, our Filament Maker is designed to handle various forms of colorants. However, settings and preparations may vary. If you want to know more, feel free to Contact Us.

Safety measures like wearing gloves and using proper ventilation should generally be observed, especially when handling powdered colorants.

This could be due to uneven mixing, inaccurate measuring, or the type of plastic used. Troubleshooting would involve revisiting these factors. If the colorant isn’t mixing well, try adjusting the settings on the Filament Maker, or consider switching to a different form of colorant.

Our GP20 Plastic Shredder is meticulously engineered to optimize the shredding process, transforming plastic waste into shreds suitable for filament extrusion. Simultaneously, our Filament Maker is designed to convert those shreds or plastic pellets into high-quality recycled filament. Both pieces of equipment are crafted with precision and innovation, making them indispensable tools for your journey toward creating recycled filament. With user-friendly features and robust performance, they ensure your plastic waste is effectively processed and converted into recycled filament, a topic we've extensively covered in this blog.

As you embark on your sustainable 3D printing adventure, our GP20 Plastic Shredder and Filament Maker stand as testaments to our commitment to empowering individuals and businesses with the tools necessary to positively impact the environment. Discover how this innovative duo can revolutionize your approach to filament recycling and enhance your contribution to a greener future.

Sure, you can mix colorants to create your unique shade, but it's not just about throwing different pigments together. Mixing colorants requires precision and understanding of how each pigment interacts with the other and the plastic. We recommend running small tests to check the compatibility and color outcome. This way, you can refine your custom color without wasting too much material.

Clumping or uneven distribution can throw off the entire appearance of your 3D-printed object. To prevent this, proper mixing is essential. Some folks opt for specialized mixing equipment or even anti-caking agents to ensure an even blend. If you're using a machine like a filament maker, make sure it offers robust mixing capabilities. Remember, a well-mixed filament leads to a well-printed masterpiece!

Delve Deeper into the World of Colorful Filaments

Master Your Material Selection

Elevate your 3D projects with our material selection guide.

Create Carbon Fiber Filament

Your go-to guide by 3devo. Master the basics, dodge pitfalls, and print like a pro!

%20-%20instasize.png?width=800&height=640&name=MicrosoftTeams-image%20(40)%20-%20instasize.png)

ABS vs PLA Filament

Your complete guide to mastering ABS and PLA filaments is here.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)

.jpg?width=3264&height=2448&name=MicrosoftTeams-image%20(47).jpg)

.jpg?width=3264&height=2448&name=MicrosoftTeams-image%20(48).jpg)