Share this

Introducing the Filament Maker TWO: Filament Extrusion Redefined

by 3devo on Nov 7, 2023 9:00:00 AM

.png?width=1501&height=1000&name=Banner%20Images%20(6).png)

Introduction

Welcome to the cutting-edge of 3D printing innovation—meet the Filament Maker TWO, the latest masterpiece from the 3devo family. Designed to revolutionize how we think about and produce 3D printing filaments, the Filament Maker TWO isn't just an upgrade; it's a leap into the future of FDM technology. Here's why the excitement is through the roof!

How the Idea Started

You know how sometimes the best ideas come up when you’re just chatting and sharing experiences? Well, that's exactly what happened with our new project. Right after a fair, full of engaging talks with people who use our products, the idea just clicked.

Our journey with the original Filament Maker ONE taught us much about the dreams and challenges innovators face in 3D printing. After seven years of success, we started to hear the voice of progress from the trenches - our core clients and industry partners were reaching the limits of what the first model could achieve. This wasn't just feedback; it was a clarion call for evolution. With our commitment to empower and propel 3D printing innovations, the development of the Filament Maker TWO became inevitable. The inspiration was clear: our clients' desire to push beyond current boundaries and unlock new possibilities in material science.

We heard what you all were saying: you wanted more from your tools. So, we took that feedback seriously and got to work. We wanted to make something that not only hits the mark for what you need right now but also paves the way for what you’ll want down the road.

Enter the development of our latest addition to the family - The Filament Maker TWO. It’s more than just an upgraded machine; it’s a leap forward in technology, built to make things easier, more efficient, and a lot more fun for anyone who loves to create with 3D printing.

Client-Driven Features and Improvements

The Filament Maker TWO's blueprint is drawn from the rich tapestry of user experiences. The detailed feedback translated into significant enhancements, like advanced sensor technology, which provides more precision and control in the filament-making process. We didn't stop at technical upgrades; we knew that a smooth user experience is critical for creativity to flow uninterrupted. So, we've refined the user interface and eliminated quirks like unexpected machine resets during data logging. Each feature is a response to real needs, ensuring our clients can reach new heights in their innovative pursuits.

Understanding the Filament Maker TWO

The Filament Maker TWO is perfect for 3D printing innovators looking to experiment with new materials. Designed for advanced compounding, it’s great for mixing novel materials or adding additives straight into polymers. It’s not trying to compete with industrial extruders, but it’s a nimble, cost-effective alternative that speeds up material innovation.

You can choose between two types of screws—fusion for more complex material blending, or highflow when you need higher output. This flexibility means whether you're pushing material boundaries or scaling up production, the Filament Maker TWO has you covered with consistent quality and reliability.

-2.png?width=1920&height=1080&name=Untitled%20design%20(1)-2.png)

.png?width=800&height=640&name=Images%20for%20website%20(Correct%20resolution).png)

A Splash of Color in the 3D Printing World

Now, onto a more personal note: why blue for the Filament Maker TWO?

Our signature Midnight Blue isn’t just a color—it’s part of who we are. It represents the innovation, precision, and design that defines us. As we continue to push the limits of 3D printing, this iconic blue stands out, much like Ferrari’s red does in the car world. It’s bold, it’s sleek, and it perfectly captures the blend of performance and style that sets us apart in the industry.

Features: A Closer Look at the Advanced Capabilities

The Filament Maker TWO packs a punch with features that cater to the very core of filament making:

- Advanced-Data Monitoring: With precision sensors and tailored visualizations, expect data-driven results that enhance research quality.

- Control Mastery: The extrusion process is under your command with a more potent extruder, hardware stability, and an accessible interface.

- Room for Creativity: A user-friendly design with minimal downtime promotes innovation through experimentation.

Advanced-Data Monitoring: Data at Your Fingertips

Data drives innovation, and the Filament Maker TWO’s advanced monitoring features take that to the next level. With smart sensors and tailored visualizations, it offers researchers precise, real-time insights that can fuel their breakthroughs. The three-axis high-speed camera system is a standout feature, keeping a close eye on filament diameter and roundness for top-tier accuracy. It's all about giving researchers the detailed data they need to push the limits of what’s possible.

.png?width=1501&height=1000&name=Filament%20Maker%20TWO%20(2).png)

Control Mastery: Steering the Extrusion Journey

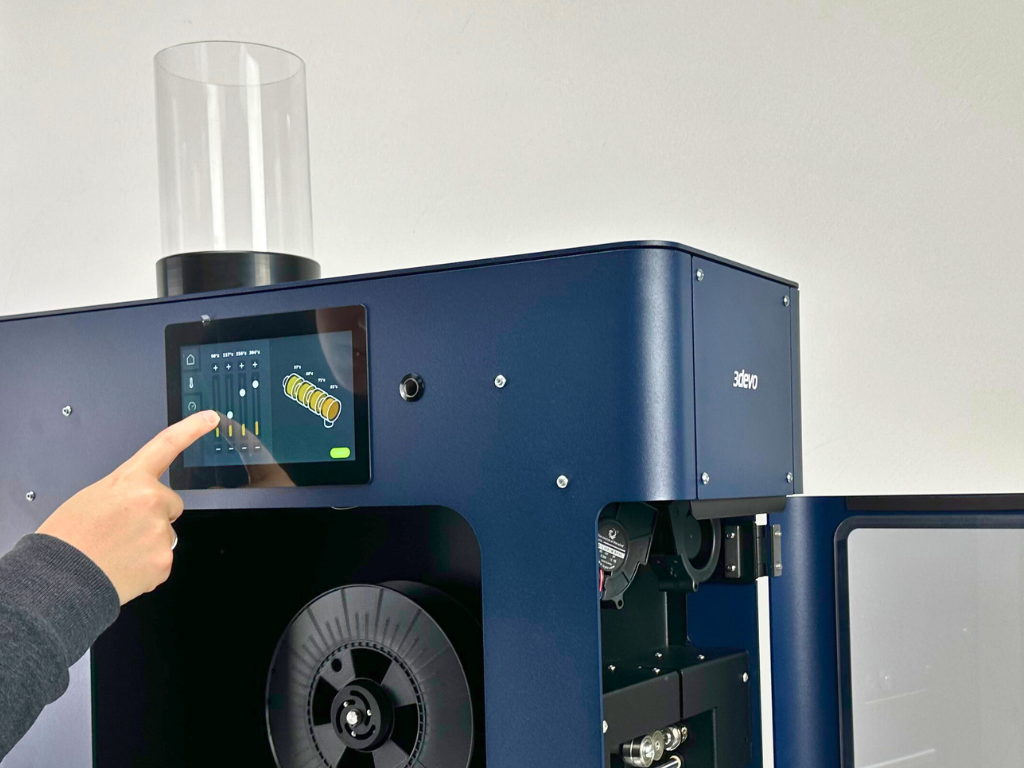

The mastery of the extrusion process rests comfortably in your hands with the Filament Maker TWO. A more robust extruder and reinforced hardware guarantee stability like never before, coupled with an intuitive touchscreen interface that puts control at your fingertips. The motor and gearbox combination has been upgraded for a more stable drive, and RPM fluctuations are minimized virtually eliminated, ensuring consistent quality. A longer screw enhances the melting and mixing capabilities, and improvements to the puller and winder system provide fine control over filament tensioning and spooling, leading to superior filament quality.

Room for Creativity: Minimized Downtime, Maximized Innovation

Innovation often involves a trial-and-error approach, and the Filament Maker TWO is designed to support this creative journey. The user-friendly design reduces downtime significantly, allowing for quick recovery from mistakes. Components such as the nozzle, die-head, insulation sleeve, machine housing, and screw are all easily removable, making cleaning and maintenance a breeze and fostering an environment ripe for experimentation. This encourages users to push boundaries without the fear of long pauses or cumbersome machine upkeep.

.png?width=400&height=400&name=MicrosoftTeams-image%20(12).png)

Future-Proof Technology: An Investment that Grows with You

The Filament Maker TWO is not just a machine for today but a companion for the future. Its hardware is built to accommodate more than what's currently required, setting the stage for continuous improvements through feature updates. The scalable electronics mean that the Filament Maker TWO is a filament extruding ecosystem designed to evolve, ensuring it will remain at the cutting edge for years to come. Features like contamination detection in the filament are among the advanced updates to look forward to, reinforcing our commitment to continuous innovation and adding value for our customers over time.

New Optical Sensor

The Filament Maker TWO ushers in a revolutionary advancement in filament production accuracy with its state-of-the-art Optical Sensor. Boasting a leap in precision, this sensor is five times more accurate than its predecessors, thanks to enhanced dimensionality and a robust 3-axis design. Capable of scanning at a rate of 25 times per second, the sensor meticulously assesses the filament's roundness, ensuring that each measurement is not only rapid but also exceptionally precise. The improved optics are specifically engineered to reduce interference from ambient light, allowing for uninterrupted data integrity. This heightened level of accuracy ensures that the puller speed is adjusted only when necessary, preventing over-correction for minor anomalies that do not affect the filament's printability. With this enhanced sensor, the Filament Maker TWO promises increased reliability, giving users the confidence that they will consistently achieve the highest quality of printable filament.

.png?width=800&height=640&name=Images%20for%20website%20(Correct%20resolution).png)

Detailed Feature Insights

Enhanced Specific Features for Experimentation and Innovation:

- The easily removable nozzle and die-head facilitate thorough cleaning and swift changes in the configuration.

- An insulation sleeve around the extruder and heaters can be easily replaced or opened, minimizing maintenance efforts.

- The machine's panels are designed for easy removal, ensuring stability even during maintenance tasks.

- A longer cooling path and a cooled hopper with temperature monitoring enable precise control over material handling, vital for experimenting with challenging materials.

Superior Extrusion Process Control:

- Touchscreen UI brings seamless machine control, streamlining the entire extrusion process.

- Rapid heating and stabilization of temperatures through powerful heaters enhance efficiency.

- A lengthier extruder screw improves melting, pressure, and mixing capabilities, empowering the creation of complex materials.

- Enhanced clamping tension control in the puller prevents filament deformation, ensuring perfect roundness.

The Filament Maker TWO's Role in Educational and Research Settings

In the landscape of academia and institutional research, the Filament Maker TWO stands as a valuable tool. It invites PhD researchers, students, and educators to transform theoretical material concepts into tangible innovations. The Filament Maker TWO can support a variety of projects, from exploring novel biomaterials to optimizing sustainable manufacturing practices. It's not just a machine; it's a catalyst for discovery, providing a practical platform for pushing the frontiers of knowledge and driving the 3D printing industry into the future.

Sustainability and Waste Reduction with Filament Maker TWO

In an era where sustainability is not just valued but vital, the Filament Maker TWO rises to the occasion. By transforming plastic waste into viable 3D printing filament, it becomes an instrument of the circular economy. It's about giving materials a second life, reducing waste, and inspiring our clients to integrate eco-consciousness into their workflow. With Filament Maker TWO, sustainability becomes an integral part of innovation, allowing creators to leave a positive footprint on the planet while they shape the world with their ideas.

Evolution of Innovation: The Next Leap with Filament Maker TWO

Building on the solid foundation laid by the Composer and Precision series, the Filament Maker TWO is not merely an incremental update; it's a leap into the future of desktop filament extrusion. As we move beyond the benchmarks set by its predecessors, the Filament Maker TWO introduces a host of enhancements and new features that redefine what's possible in desktop filament creation.

As we usher in the new era with the Filament Maker TWO, we're not just observing the evolution of innovation; we're actively shaping it. This machine isn't just about matching the capabilities of a professional setup; it's about compacting those capabilities into a form factor that sits comfortably on your desktop. The Filament Maker TWO is your personal filament factory, empowering you to push boundaries, innovate, and create with confidence and precision.

The Philosophy Behind Our Approach

We're not just here to sell you a machine. We're here to guide you through uncharted project territories. By understanding and mapping out your needs, we ensure that you won't face those 'oh no' moments when it's too late. When you win, we win – it's as simple as that.

Our commitment to partnership means we're always learning from our customers, which in turn fuels our product development and process enhancements. After all, if it's not working for you, it's not working for us.

Launching into a New Era

Since its grand showcase at Formnext in Frankfurt in November 2023 and 2024, the Filament Maker TWO has generated significant excitement. With availability now open, you can purchase it today! The estimated delivery time is approximately 8 weeks. If you have any questions, don’t hesitate to reach out—we’re here to help.

Share this

- November 2025 (1)

- October 2025 (1)

- March 2025 (1)

- January 2025 (1)

- December 2024 (2)

- November 2024 (2)

- October 2024 (4)

- September 2024 (2)

- August 2024 (3)

- July 2024 (6)

- June 2024 (3)

- May 2024 (2)

- April 2024 (1)

- March 2024 (1)

- January 2024 (1)

- November 2023 (2)

- October 2023 (5)

- September 2023 (2)

- August 2023 (1)

- July 2023 (1)

- May 2023 (1)

- December 2022 (2)

- June 2022 (1)

- May 2022 (2)

- April 2022 (2)

- March 2022 (6)

- February 2022 (2)

- January 2022 (3)

- December 2021 (3)

- November 2021 (3)

- October 2021 (2)

- September 2021 (3)

- August 2021 (3)

- July 2021 (2)

- June 2021 (1)

- March 2021 (1)

- October 2020 (1)

- June 2020 (1)

- May 2020 (1)

- April 2020 (4)

- November 2019 (1)

- July 2019 (2)

- June 2019 (1)

- May 2019 (1)

- March 2019 (1)

- November 2018 (1)

- September 2018 (1)

- January 2018 (1)

- October 2017 (1)

- September 2017 (1)

- July 2017 (1)

- June 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (3)

- November 2016 (2)

- October 2016 (1)

- May 2016 (2)

- August 2015 (2)

- July 2015 (1)