Turning 3D Printing into a

Closed-Loop Cycle

Discover our streamlined ecosystem that delivers an industrial process to the convenience of your workspace.

Delivering a smart, cost-effective, and adaptive closed-loop production facility — The complete filament-making solution.

PRE-STEP 1

Shred it (Recommended)

Many thermoplastics can be recycled and converted into filament for 3D printers. With our shredder, we put our plastic waste to good use. Grinding down old plastics into pellets with ease and effortless operation. Once the regrinds have been created, it can then be processed by our filament maker.

PRE-STEP 2

Dry It

Moisture can make it nearly impossible to produce quality 3D printing filament. By drying granulates prior to producing filament, this process can enhance the performance characteristics of the filament produced.

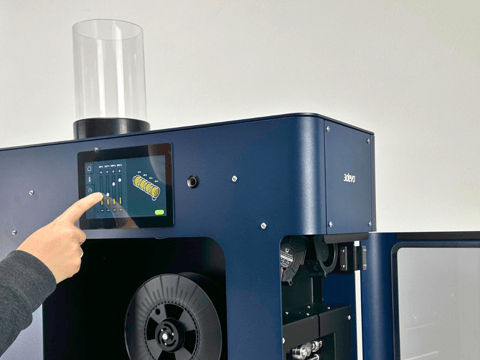

STEP 1

Melt It

Whether we’re repurposing shredded regrinds or using manufactured granulates in our filament maker — We can melt almost any polymer, including high temperature thermoplastics and metal powdered combinations. From there, our filament maker extrudes customized filament with precise roundness and accurately guides it to the spool.

STEP 2

Spool It

How the filament is rolled on the spool makes a world of difference. That is why the extrusion and spooling process in our filament makers are well-integrated, guaranteeing neat spools every time. Enhancing the 3D printing experience with quality filament through consistent diameter tolerance.

STEP 3

Print It

Finally, we are left with high-quality 3D printing filament. From turning old prints into filament and new filament into fresh prints – We developed a closed-loop cycle. Delivering a smart, cost-effective, and adaptive solution to 3D production.

Let's Talk About Your Project

Schedule a free online video consultation with one of our material specialists to discuss the details of your project.