Industrial EngineerConverting Waste into a Valuable Resource

Trusted By the Best Engineers:

Lower Costs, Enhance Efficiency, Promote Sustainability

Improve your company's plastic recycling and waste management with 3devo's scalable and flexible solutions.

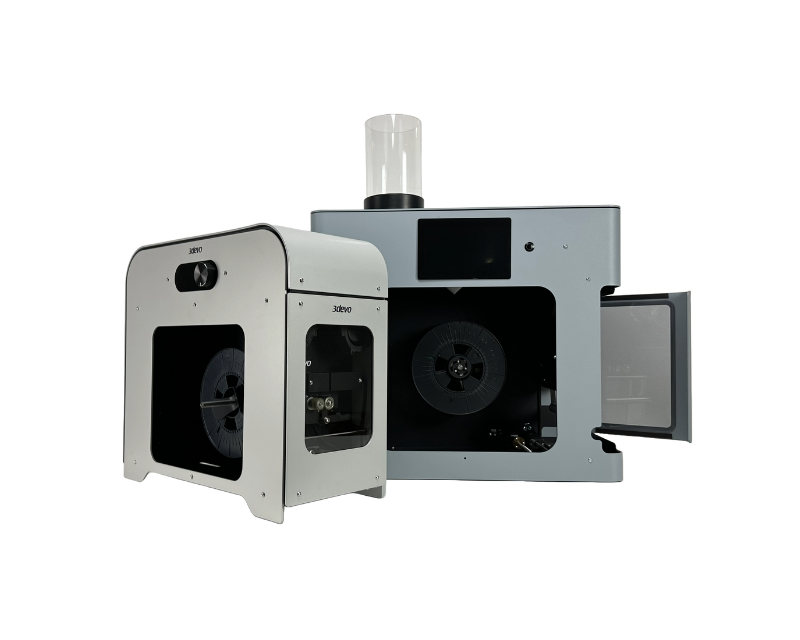

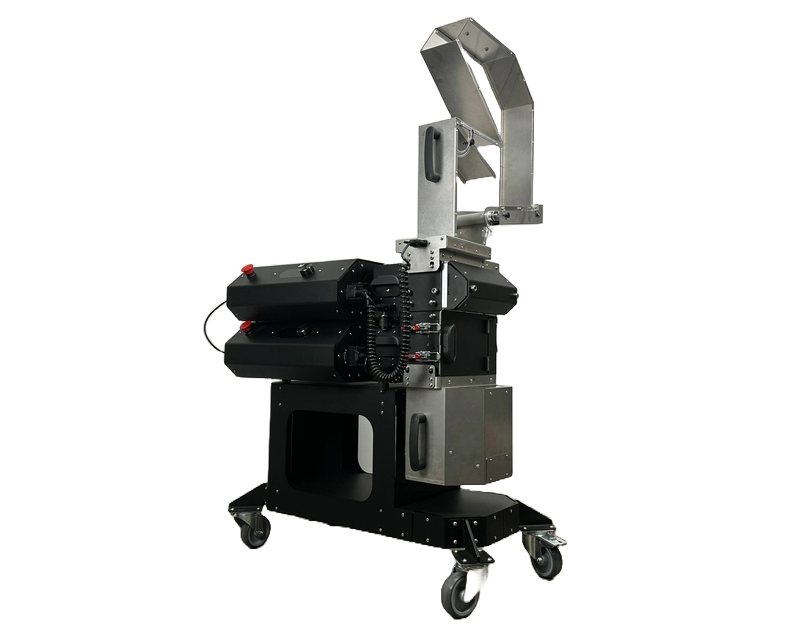

Our Filament Makers and Plastic Shredder turn plastic waste into high-quality 3D printing filament, enhancing the efficiency of your processes, lowering costs, and promoting sustainability.

Challenges & Solutions

At a glance

Industrial Quality

After Sales Support

Easy Maintenance

No Set Up Needed

Onboarding

Maximizing ROI

Pain Point: The risk of wasting time and money on inefficient solutions.

3devo's Solution: Durable, cost-effective machines minimize financial risk and guarantee ROI. Plus, our validation services speed up your process, saving you even more time and resources.

Material Compatibility & Validation

Pain Point: Wasting time and resources on non-compatible materials.

3devo's Solution: With our validation services, extensive materials database, and expert support, finding the right fit for your projects is streamlined, eliminating the risk of failure.

Simplifying Implementation & Maintenance

Pain Point: The complexity of integrating new solutions to your existing processes, and the time required for maintenance.

3devo's Solution: User-friendly machines designed for easy setup and minimal maintenance, ensuring seamless integration and operation.

Future-Proof & Scalable Solutions

Pain Point: The need for solutions that can adapt and scale with evolving project demands.

3devo's Solution: 3devo's dedication to innovation guarantees that our solutions are designed to meet not only current needs but also future demands. Our adaptable business model allows you to effortlessly expand your operations whenever and for however long you require.

How We Do It

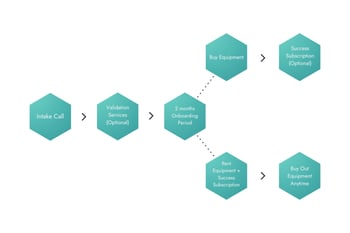

Recommended Journey

Talk to Us

Schedule a consultation with one of our customer success agents to discuss your project and receive a complimentary evaluation on the materials and ROI.

Eliminate Risks

Get a validation service and get insights about your materials extrudability and printing quality.

Buy the Equipment

Purchase the equipment you need and gain full autonomy over the machine(s).

Start your Onboarding

Our team will assist you in getting started quickly and efficiently with our expert onboarding process.

Optional Support

Choose to opt in or out of our Project Consultancy.

Materials

Common waste and commodity polymers

| PP | PET | PLA |

| HDPE | PETG | ABS |

| LDPE | PS | PHB |

Engineering polymers

| TPU | PCL | PPS | PA6 |

| TPE | PC | POM | PA66 |

| PVA | ASA | PA | PA12 |

High performance polymers

| PEEK | PEI | PSU |

| PEKK | PPSU |

Projects Like Yours

European Space Agency

How do researchers at ESA have the freedom to innovate – without wasting resources in the process.

Fontys University

How Fontys gained the ability to expand their polymer development studies – at a fraction of the cost.

Sika Automotive

How Sika Automotive managed to reduce their production time – for their cavity sealers -from weeks to days.

Need a starting point?

We provide material analysis, tailored workshops and dedicated support to guide you to success.

Hear From Our Clients

Frequently Asked Questions

How can 3devo help in maximizing ROI on plastic waste management?

Our Filament Makers and Shredder solutions transform plastic waste into high-quality 3D printing filament. This not only helps in reducing material costs by repurposing waste but also enhances your sustainability profile, potentially leading to tax benefits and improved market positioning.

Are my materials compatible with your machines?

Yes, our equipment is designed to work with a wide range of thermoplastics – from common ones like PLA and ABS to high-performance plastics like PEEK and PEI. We also offer a validation service to test your specific materials for extrudability and printing quality.

What if I'm unsure about the suitability of 3devo's solution for my project?

Schedule a consultation with our customer success team for a complimentary evaluation of your project's materials and ROI. We also offer a two-month trial to test our equipment with your materials. Schedule a call here.

Do I need to set up the machines myself?

No, there's no setup needed on your part. Our expert onboarding process ensures that you can start using the machines immediately after receiving them.

How does 3devo assure future-proof and scalable solutions?

Our solutions are designed to be modular and scalable. You can start with a small setup and easily expand your capacity with our flexible plans, starting at 250€ per month.

Can I purchase your products directly?

Yes, our products are available for purchase. Just request a quote, and we’ll guide you through the process and provide all the details you need.

What should I do with failed 3D prints and other 3D printing waste?

Our GP20 Shredder can turn failed prints and other waste into granulate, which can then be converted into new filament by our Filament Maker, effectively recycling your 3D printing waste.

/3devo%20Logo%20Borderless%20-%20Dark%20Mode.png?width=200&height=64&name=3devo%20Logo%20Borderless%20-%20Dark%20Mode.png)