Filament Makers

Dutch-made extrusion systems for material development and recycling.

Compare the Filament Maker ONE and TWO — trusted worldwide by R&D teams, universities, and innovators, shaping the future of polymers.

Filament Makers

Our Filament Makers

Empowering Innovation One Filament at a Time

Filament Maker TWO

3devo introduces our brand new Filament Maker TWO. A cutting-edge 3d printing filament extruder with innovative technology with advanced features.

Filament Maker ONE Composer

The Composer offers an easy-to-use

and durable solution for creating

custom 3D printing filament in a sleek, compact design.

Filament Maker ONE Precision

The Precision model delivers top-notch,

high-temp filament extrusion

with speed, consistency, and

user-friendly operation.

Trusted By the World's Top Engineers and Researchers:

Kickstart your Project

Evaluate your project's potential effortlessly with our complimentary project builder.

Filament Maker TWO

Experience extrusion power and versatility with the Filament Maker TWO. This advanced filament extruder and research platform allows you to explore new filament materials with increased stability, precision, and ease of use. Perfect for research, prototyping, recycling and material development, it features high motor torque, optimized heating, and advanced sensors for top-quality results.

Filament Maker ONE

The power of the Filament Maker ONE lies in its precision and versatility. Explore high-temperature capacity, precise diameter control, and advanced material mixing, making it ideal for diverse 3D printing applications. Its durable extruder screw and multi-zone heating ensure consistent, high-quality filament production.

Create Filament from 300+ Materials

Common waste to recycle

| PET | PLA | PP | HDPE |

| PETG | ABS | PS | LDPE |

| PC | PHB |

Engineering polymers

| TPU | POM | PA6 | PVA |

| TPE | PCL | PA66 | PA |

| ASA | PA12 |

High performance polymers

| PEEK | PEI | PSU |

| PEKK | PPSU |

Additives and composites

Real-Life material experimentation highlights with the Filament Makers

Take a look at what some of the leading research institutions and universities are achieving with our filament makers by experimenting with various composites and material blends.

Strengthening ABS with Nano Titanium Nitride

Scientists at the Hellenic Mediterranean University enhanced ABS filaments with nano Titanium Nitride using a 3devo Filament Maker, boosting their strength and durability for superior 3D printing.

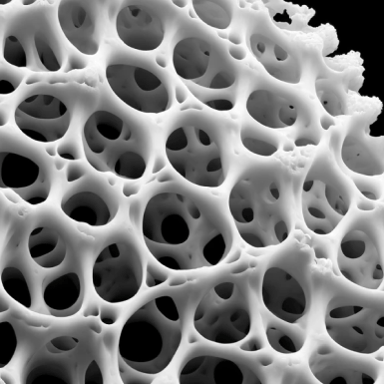

Creating Polymer-Nickel Composite Filament

Researchers at Warsaw University of Technology utilized our Filament Extruder to create an enhanced PLA, PVB, and ABS composite filament with nickel, ideal for high-performance, porous 3D printing structures.

Stronger 3D Printing with PP-Tungsten Carbide Composite

Researchers at the Hellenic Mediterranean University have created a stronger, more durable 3D printing material by merging polypropylene with tungsten carbide, perfect for high-quality parts.

Limitless Material Composites at your fingertips

Our Filament Makers, equipped with advanced extrusion technology, empower you to effortlessly craft unique material composites. Tailor strength, flexibility, or heat resistance to meet your project's needs, unlocking innovation and elevating your 3D printing with customized filaments.

Types of Producible Filament

Experiment with unlimited material composites using our Filament Extruders. Here are some examples of unique filament that has been successfully extruded by our clients.

Carbon Fiber Reinforced Filament

Enhance the strength and rigidity of your 3D printed parts by combining PLA with carbon fibers. This composite material is perfect for creating lightweight yet robust components.

%20powder%2c%20resembling%20the%20texture%20of%20flour.%20The%20powder%20is%20white%20and%20appears%20finely%20granulated%20with%20a%20s.webp?width=384&height=384&name=DALL%C2%B7E%202024-05-28%2011.03.40%20-%20A%20close-up%20view%20of%20SLS%20(Selective%20Laser%20Sintering)%20powder%2c%20resembling%20the%20texture%20of%20flour.%20The%20powder%20is%20white%20and%20appears%20finely%20granulated%20with%20a%20s.webp)

SLS Powder Filament

Reprocess wasted SLS powder into high-quality filament for FDM printing. This cost-effective approach enables endless possibilities for recycling and material reuse.

Plastic Waste Filament

Collect plastic waste from tourist attractions and water-based heritage sites in Vietnam to create filament. Transforming bottle waste into usable filament supports recycling and sustainability.

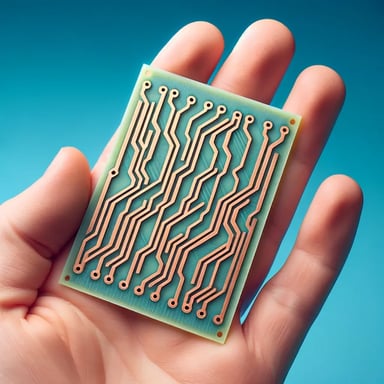

Conductive Filament

Create functional electronic circuits by using conductive filament in your 3D printing projects. Ideal for printing PCBs, this filament allows for seamless integration of electronics into your designs.

%20(1).png?width=452&height=384&name=3d%20printed%20object%20with%20wood%20filament%20(1)%20(1).png)

Organic Filament Blends

Clients mix coffee grounds and wood fibers with standard filaments, adding unique aesthetics and contributing to sustainability. Reusing coffee grounds supports eco-friendly practices.

Filament for Biomedical applications

Suitable for soft tissue regeneration, bone tissue engineering, personalized medicine, and pharmaceutical drug development.

Compare Filament Makers

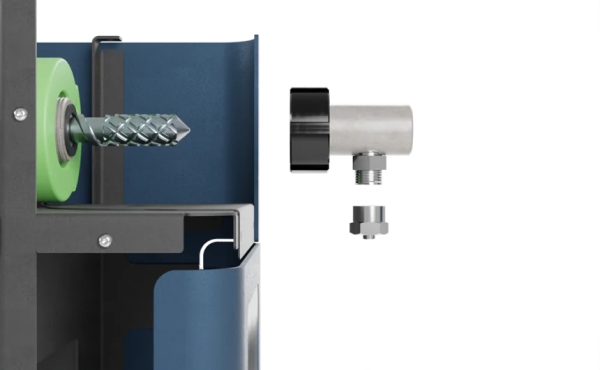

Extruder Screws

Your Material's Extrudability?

Schedule a Melt Flow Index Test for €200 per hour to discover the potential of your polymers.

Filament Maker TWO

VS

Filament Maker ONE

In addition to the specifications, our latest filament maker features improvements that enhance production quality, user experience, and efficiency.

Dive deeper into the specifics:

Intuitive Operation and Maintenance

- User-Friendly Design: Intuitive process for easy operation and

simplified spooling. - Modular Components: Quick-release parts for hassle-free cleaning

and maintenance. - Enhanced Insulation: Removable insulation with Velcro.

- Optimized Cooling: A controlled hopper cooler ensures stable

extrusion temperatures. - Precision Monitoring: In-built temperature monitoring for

consistent output. - Efficient Spooling System: Features a Tensioner Arm Swing for

perfect winding.

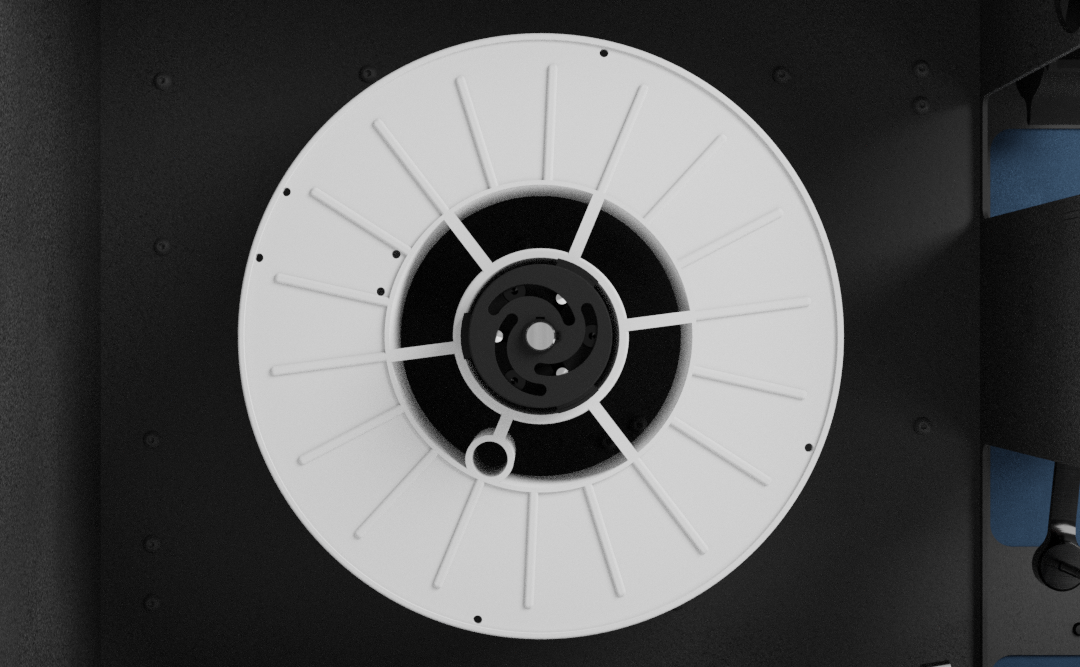

Precision Spooling with Enhanced Flexibility

- Automated Tension Control: The new tensioner arm automatically adjusts the tension, ensuring consistent winding without manual intervention.

- Spool Chuck Mechanism: Easily switch between spool sizes for maximum flexibility, accommodating a broader range of spool dimensions.

- Customizable Spool Parameters: Set specific spool dimensions directly on the device to achieve perfectly sized and neatly wound filament spools every time.

- Increased Spooling Area: Expanded room for spooling allows the use of larger spools, up to 3kg.

User-friendly and easy to control

Experience user-friendly control with the new Filament Maker TWO series. Unlike previous models with an OLED display and a single control button, the newest models feature an embedded 7" LCD touchscreen for effortless access to all filament maker functions.

Wirelessly connect the Filament Maker to your computer via an ethernet connection to view the measurement data and keep your machine updated with the newest firmware.

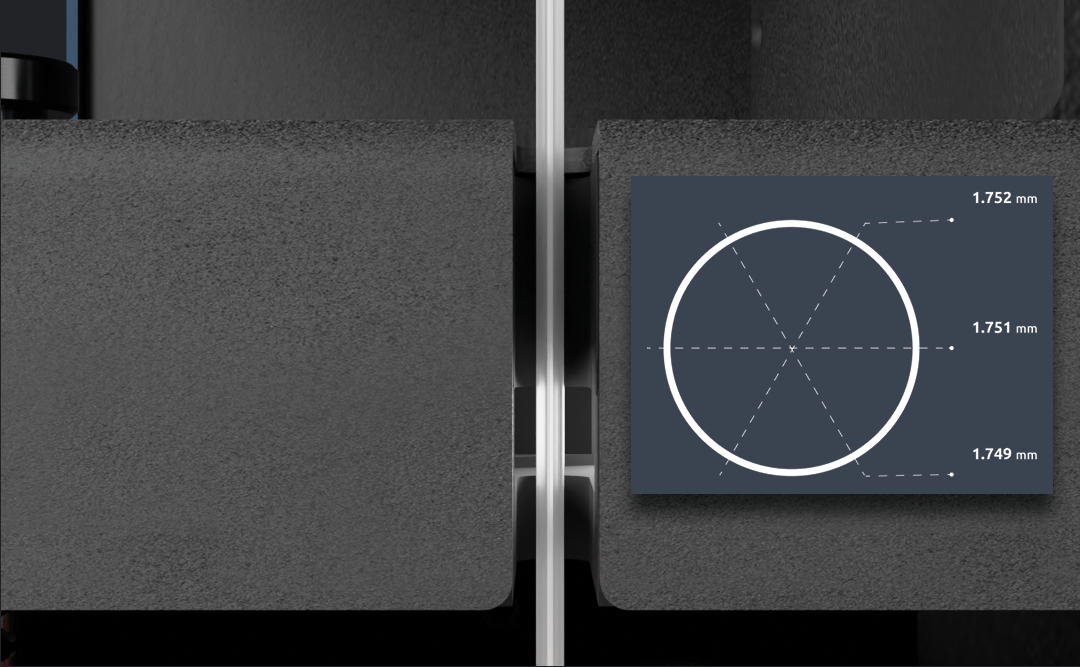

Advanced New Sensor

- 10 µm resolution

- Advanced vision-based diameter sensing

- Camera-assisted filament calibration

- Real-time visual diameter inspection

- Enhanced accuracy with 3-axis design

- Improved optics reduce interference from ambient light

This compact, intelligent sensor system is designed for the highest standards in filament quality, perfect for innovators in technical and educational fields.

Create your own 3D printing materials

with our Filament Extruders

Compounding

Homogenous Blends

Custom Colors

Enhanced Properties

Infuse your filament with metallic powders or other functional additives to achieve specific performance characteristics

Quality Control

Assure the consistency and quality of your custom filament with our precise extrusion technology, ensuring reliable printing results every time.

Flexible Formulations

Experiment with a blend of pre-compounded materials or mix your own for custom-tailored properties, suited to your project’s unique demands.

Filament Makers for Advanced Applications

Recycle Plastic waste

Give your plastic waste a second life by recycling bottles, 3d prints and more into filament. Embrace sustainability with our Filament Extruders by 3D printing with recycled filament.

Research and Development

Create innovative filament composites with our Filament Makers. Blend various plastics, incorporate additives like nanodiamonds or ceramics, add colorants, and more. Enjoy the freedom to experiment and customize filaments to suit your specific applications.

Prototype with Precision

Stay ahead in 3D printing with our advanced Filament Makers. Rapidly prototype and validate new materials into viable filaments with precision and flexibility. Ensure project success with 3devo's cutting-edge technology.

Engaging Students and Researchers in Filament Creation and Recycling

Transform the way students and researchers learn with our Advanced Filament Makers. By directly engaging in the process of making custom 3D printing filament, learners can explore unique material properties and participate in sustainable plastic recycling projects. This hands-on filament creation experience fosters practical learning, encourages innovation in material science, and promotes sustainability education in academic environments.

%20(2)%20(1).jpg?width=6240&height=3512&name=Educator%20Blog%20pic%201%20(1)%20(2)%20(1).jpg)

Enhancing Industrial Prototyping with Industrial Filament Makers

Achieve faster prototyping cycles and cost-effective small batch production with our industrial-grade Filament Maker ONE and Filament Maker TWO. These machines are designed for rapid material testing and design validation, empowering industries to quickly iterate on new designs and test various filament materials like ABS, PLA, PEEK, and PEKK. Reduce your time-to-market and development costs compared to traditional manufacturing methods by leveraging these precision extrusion systems for industrial prototyping.

Sustainable Plastic Recycling for Manufacturing Processes

Drive sustainability in 3D printing and manufacturing processes by transforming plastic waste into high-quality filaments using our Filament Makers. This eco-friendly recycling method helps companies align with circular economy principles by reducing plastic waste and reusing it to produce new, usable materials. Our machines support green manufacturing and help you lower your environmental footprint while maintaining efficiency in production.

-min.png?width=1920&height=1080&name=Filament%20Makers%20Page%20(1920%20x%201080%20px)-min.png)

Filament Maker Case Studies

Revolutionizing Breast Reconstruction with Lattice Medical’s 3D Technology

Mattise 3D technology revolutionizes breast reconstruction by offering a more accessible and cost-effective solution.

Advancing Sustainable MJF Printing with AZ3D’s Eco-Friendly Filament Solution

AZ3D, a Tucson-based prototype manufacturer, repurposes unusable nylon MJF material into eco-friendly 3D printing filament.

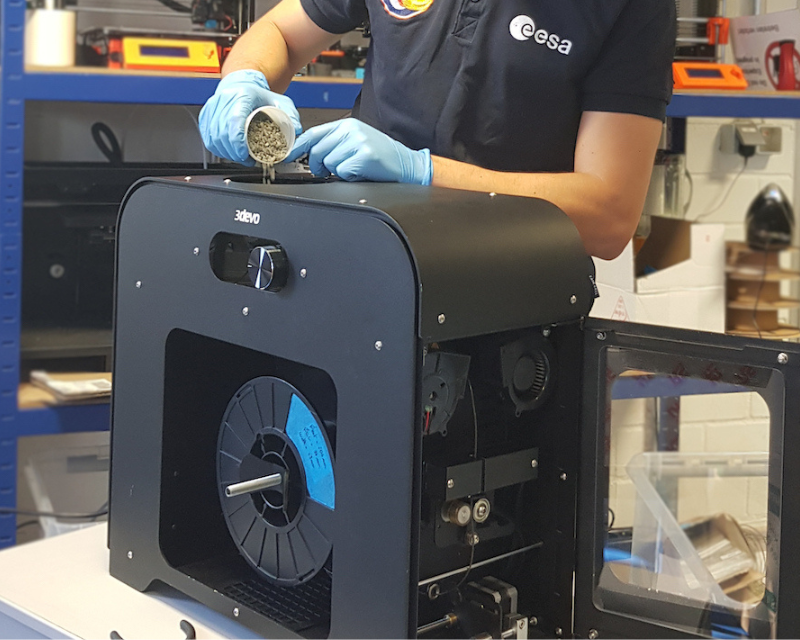

Accelerating Space Exploration with ESA’s Innovative 3D Printing Research

The European Space Agency uses the Composer 450 for space research, focusing on prototyping with 3D printing.

Advancing Sustainable Automotive Practices with Audi’s Circular 3D Printing Initiative

Audi uses 3devo’s solution to recycle plastic waste into 3D printed tools, supporting their Mission: Zero for sustainable production.

Maximize Your Filament Extrusion Potential

Whether you're diving into plastic recycling or looking to upgrade your Extrusion Setup, our solutions offer flexibility and innovation. Discover how to turn waste into high-quality 3D printing filament with our full recycling system, or explore upgrade options to make the leap to our lastest Filament Extruder.

Full Recycling System

Recycle failed prints, prototypes, or scrap material into usable filament with our complete setup. Our Plastic Shredder and Filament Extruders work together to give you consistent, high-quality results

Trade-in loyalty program

Ready for an upgrade? Trade in your Filament Maker ONE for a €2,000 discount and add the Filament Maker TWO to your setup. Experience smoother extrusion, smarter features, and a streamlined workflow designed for better results.

Kickstart your Project

Evaluate your project's potential effortlessly with our complimentary project builder.

Kickstart your Project

Evaluate your project's potential effortlessly with our complimentary project builder.

Read our Filament Maker Innovations

Formnext 2025 Recap: Materials, Workflows & Real Insights

From Waste to Filament: Experience 3devo’s Dutch-Made Ecosystem at Formnext 2025

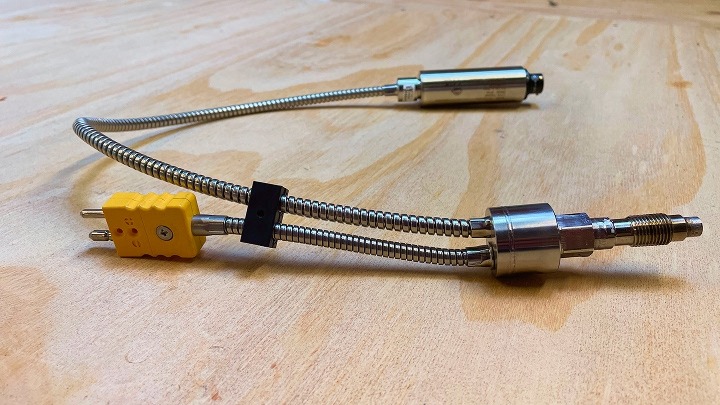

How We're Developing a Pressure Sensor for the Extrusion Process

/3devo%20Logo%20Borderless%20-%20Dark%20Mode.png?width=200&height=64&name=3devo%20Logo%20Borderless%20-%20Dark%20Mode.png)

.png?width=276&height=184&name=Filament%20Maker%20TWO%20(2).png)