FAQ

Whether you are new to the field or an experienced professional, we provide the solutions you need.

At 3devo, we've always been more than a company - we are pioneers at the forefront of the 3D printing revolution. As we embark on a thrilling new chapter, we're transitioning from being solely a hardware provider to adopting a Project Led Growth (PLG) model.

As of 2024, our focus has shifted to partnering and collaborating with clients to achieve shared objectives. While our acclaimed products like the Filament Maker TWO Fusion and HighFlow Series, Filament Maker ONE Composer and Precision Series, and GP20 Shredder Hybrid remain at the heart of our offerings, we're enhancing our approach to include consultancy and educational services under flexible leasing agreements. This transition is an exciting development in our story of empowerment and innovation, marking a new era of closer collaboration and greater achievements in the world of 3D printing.

At 3devo, we specialize in providing innovative solutions for 3D printing and filament extrusion, with a focus on material experimentation and recycling. Our range of equipment includes:

-

Filament Maker TWO Series: Our latest advancement in filament-making technology. This series includes the Fusion and HighFlow models, designed to enhance your 3D printing and material innovation. Learn more about the Filament Maker TWO series and it's features.

-

Filament Maker One Series: Including the Composer 350/450 and Precision 350/450, these machines have set the standard for desktop filament extrusion, offering reliable and high-quality filament production. Explore our original Filament Makers.

-

GP20 Plastic Shredder Hybrid: A versatile solution for shredding and granulating various plastics, making recycling more accessible and efficient. Discover the GP20 Plastic Shredder Hybrid.

For a comprehensive comparison of our Filament Extruder lineup, including the Filament Maker TWO series and our original lineup, visit our comparison page.

Our product range is complemented by a full spectrum of support and consultation services, ensuring that you have the right tools, knowledge, and assistance to achieve your innovative objectives.

The cost of the solution depends on the project and ranges from around €8,000 to €30,000 or above. However, we always do our best to accommodate our customers' budgets by carefully considering your needs and helping you kick-start your projects!

You can get in touch with support by going to our support platform. Select 'contact us' in the top right corner and fill in one of the available forms. We will do our best to answer you within 48 hours. Please keep in mind our operating hours are from 9:00 to 17:00 CET from Monday to Friday.

You can get in touch with sales by going to our Contact Us page. Make sure to enter your contact information. From the dropdown selection, please select how we can help you from the given options. Make sure to include as much detail as possible in the description and then click submit. We will do our best to answer you within 24 hours. Keep in mind we are open from 9:00 to 17:00 CET from Monday to Friday. You can also reach us on the phone at +31 85 876 9016.

For us, sustainability is not just a checkbox; it is an integral part of our mission, driven by a deep commitment to responsible practices that put the environment and the well-being of future generations first. At 3devo, each individual is driven by the desire to make a meaningful impact. We are passionate about creating a greener future where technological advances are matched by environmental progress. By wholeheartedly embracing sustainability, we are taking significant steps to ensure that the world we leave behind is better than the one we inherit. Our focus on solving the huge plastic waste problem is in line with our belief in the transformative power of 3D printing. With our expertise, we are bridging the gap between these two important aspects to address the sustainability challenges facing our planet.

At 3devo, our future is shaped by a relentless commitment to innovation and a deep understanding of our client's needs. We are constantly evolving, using feedback to refine our products and explore new frontiers in material development and recycling solutions. We focus on making substantial impacts in these areas, harnessing our tools to open new opportunities for innovation and sustainable practices.

We recognize the global challenge posed by plastic waste and are dedicated to transforming this challenge into an opportunity. By combining recycling with 3D printing technology, we aim to utilize existing plastics responsibly and innovatively. This approach is not only a step towards solving the plastic waste problem but also aligns with our goal of fostering sustainable solutions in the 3D printing industry.

Our journey goes beyond being a hardware supplier; we are transitioning into a more project-led, innovative company. This shift reflects our broader vision of delivering solutions that address real-world problems, especially in material development and recycling.

In line with this vision, we recently launched the Filament Maker TWO, a testament to our client-centric approach. This latest machine, developed based on valuable client feedback, showcases our dedication to continuous improvement and customer satisfaction. The Filament Maker TWO represents a significant step forward in our commitment to innovative, efficient, and sustainable solutions.

Stay tuned for future developments as we continue to expand and upgrade our equipment lineup, always guided by our clients' insights and the ever-evolving landscape of 3D printing technology. To witness our latest innovation, check out the Filament Maker TWO.

At 3devo, we offer a comprehensive solution that covers every step of the process, from recycling plastic to producing high-quality filament. We offer shredding, drying and filament extrusion machines, all with a 1 year warranty.

From the moment we dispatch your package, our guarantee ensures that your investment is in safe hands. In the rare event that your machine is damaged in transit, rest assured that our warranty will cover all costs, including damage during transit and breakage of mechanical parts, ensuring that your investment is safe.

While our guarantee provides comprehensive cover, it is important to note its limitations. The warranty does not cover claims arising from the use of unsupported materials, non-compliance with operating instructions, modification of the machine or the effects of normal wear and tear. These exclusions help to ensure that the warranty remains focused on addressing manufacturing defects and abnormal occurrences while emphasizing the importance of responsible use and care.

The decision to discontinue the AIRID Polymer Dryer was made in line with our new business strategy, focusing on the evolving needs of the 3D printing industry. Although there is no direct successor, we remain proud of its quality and performance. We assure current users of a two-year service period, during which we'll provide technical support, maintenance services, and spare parts, ensuring the AIRID Dryer continues to meet your needs.

Throughout the service period ending on February 1st, 2026, we will offer comprehensive support, including troubleshooting assistance, spare parts for maintenance, and critical updates. After the service period, we aim to continue supporting the AIRID Dryer as much as possible, though spare parts availability may be limited.

For more information or assistance, please visit our support articles on the End of Life Notice for the AIRID Polymer Dryer, AIRID Polymer Dryer Support Overview, or contact our dedicated customer service team. We are committed to a smooth transition and ensuring your continued satisfaction with our products.

Getting started

Embarking on your path of recycling and innovation is an exciting venture, and at 3devo, we are committed to helping you take those crucial first steps. Our approach to transforming sustainable practices reflects our commitment to pioneering recycling innovation.

To begin, explore our range of advanced solutions tailored to make recycling more efficient and accessible across various industries. Whether you are venturing into plastics, materials, or other sectors, our cutting-edge technology allows you to turn waste into a valuable resource. We are passionate about innovation and ensuring you have the latest tools at your disposal.

Our blog is a Valuable resource for insights and real-world applications if you are interested in learning more.

The production of 3D printing filaments requires a delicate process to ensure optimal print quality. The steps to making filament are as follows:

1. Material selection: start by choosing the right material, taking into account factors such as compatibility with the printer and the desired properties of the final print.

2. Preparation: ensure that the chosen material is properly dried to avoid moisture, which can cause defects in the fibers and affect the quality of the print.

3. Extrusion: heat the material until it reaches a molten state and extrude it through a nozzle at a controlled rate. This forms the filament's shape and diameter.

4. Cooling and sizing: the extruded filament is rapidly cooled to solidify and then passed through sizing mechanisms to ensure uniform diameter.

5. Spooling: wind the filament onto spools ready for storage and use in the 3D printer.

For those looking to get hands-on with filament production, 3devo's advanced filament extruders are an excellent choice. Our machines give you complete control over the process, allowing you to experiment with different materials and properties, ensuring you create the perfect filament to suit your needs.

If you want to dive deeper into the mysteries of How filament manufacturing and 3D printing are intertwined with innovation, you can find some enlightening information on our blog.

The Filament Maker TWO represents a leap into the future of 3D printing technology, encapsulating a spirit of innovation and a dedication to excellence. With its advanced data monitoring and enhanced extrusion control, it elevates the filament creation process into a precise, data-driven art form. The incorporation of user-friendly features and future-proof technology ensures a streamlined experience that’s both intuitive and cutting-edge.

Users benefit from an environment that fosters innovation, allowing for seamless experimentation and a reduction in downtime. The emphasis on future-proofing through firmware updates, such as contamination detection, ensures that the Filament Maker TWO is not just a tool for today but an investment for tomorrow.

Learn more about the Filament Maker TWO here.

Within this groundbreaking framework, the Filament Maker TWO offers two distinct models tailored to different aspects of the filament creation spectrum:

Fusion Model: Designed for experimentation, material compounding, and R&D, the Fusion model is the quintessential tool for creative spirits. It’s built for:

- Experimenters and Innovators: For those continuously crafting new material combinations, the Fusion model keeps pace with your creativity.

- Material Compounders: Specialists seeking to blend unique filament properties will find the Fusion model’s capabilities invaluable.

- R&D Departments: The adaptability of the Fusion model serves the broad experimental needs of research teams, fostering innovation at every turn.

HighFlow Model: Engineered for precision, the HighFlow model is the definitive solution for consistent, efficient output. It’s optimized for:

- Precision-focused Operations: When every detail counts, the HighFlow model provides the accuracy needed for precise projects.

- Stability Requirement: The HighFlow model offers robust and reliable production for operations demanding unwavering performance.

- Speed and Efficiency: High throughput without quality compromise is the hallmark of the HighFlow model, appealing to those who prioritize efficiency alongside excellence.

The Filament Maker TWO, with its Fusion and HighFlow models, doesn’t just accommodate the full range of filament creation needs—it anticipates and exceeds them. Whether pushing the envelope with new materials and processes or producing high-quality filament at scale, these models are crafted to assist innovators and professionals in achieving their goals with unmatched efficiency and precision. The Filament Maker TWO isn’t just a machine; it's a catalyst for transformation in FDM technology.

Interested in the technical details of the Filament Maker TWO? Find comprehensive specifications, including a comparison between the Fusion and HighFlow models, to help you make an informed decision. View the technical specifications and product comparison here.

The only difference between the two models is the screw configuration. The Composer screw has an additional mixing zone at its end (“pineapple” design), providing advanced homogeneity and better compounding results in the filament. On the other hand, the Precision screw has a basic metering configuration and is ideal for processing pre-compounded or virgin pellets, powders, or regrind. Check out or Filament Maker One page to learn more. If you want to know more about the differences, check out our Filament Maker Comparison page.

- Go to our Contact Form

- Enter your business contact information.

- In the last section, select Purchasing only Spare Parts / Consumables.

- Select the products that you would like us to send you.

- Hit the Submit Button

We do our best to reach out to you within 24 hours. Our opening hours are 09:00-17:00 CET from Monday to Friday.

We've got a bunch of resources on our blog that cover various aspects of 3D printing, making filament and material recycling. Here are ten articles that you might find helpful:

-

Get a handle on identifying and rectifying filament defects with our Guide to Troubleshooting Common Filament Defects.

-

Delve into the colorful world of plastics with our Complete Guide on Plastic Pigments and How Colorants Work.

-

Embark on a journey of environmental conservation with Sustainable 3D Printing: Creating and Using Recycled Filament.

-

Uncover the innovative recycling solutions 3devo is spearheading in this Insight into Unlocking Recycling Innovations with 3devo's Solution.

-

Stay abreast of the latest developments at 3devo with our 2023 Outlook: What to Expect from 3devo in the Coming Year.

-

Explore the revolutionary role of 3D printing in medical science in this Article on Revolutionizing Tissue Reconstruction with 3D Printing.

-

Pondering the purchase of a filament maker? Here's our Comprehensive Buying Guide for Filament Makers.

-

Discover how Fontys University leverages our Filament Maker for practical learning in this Case Study on Hands-on Learning at Fontys University.

-

Navigate the complexities of material selection for 3D printing with our Complete Material Selection Guide for 3D Printing Enthusiasts.

-

New to extruding carbon fiber filament? Here's a Step-by-Step Guide to Get You Started with Carbon Fiber Filament.

Extrusion essentials

Thermoplastic polymers are favored for filament extrusion in 3D printing due to their favorable characteristics, such as strength, printability, and specific material properties. When choosing a polymer for your Filament Extruder, it's important to consider the requirements of your project to ensure you select a suitable thermoplastic polymer.

-

If you're looking for cost-effective options, you might want to explore Commodity Plastics.

-

For enhanced mechanical and thermal properties, Engineering Plastics could be your go-to.

-

If your project requires exceptional durability and resistance, High-Performance Plastics are worth considering.

To delve deeper into how to make the right choice, check out our article on our support platform or explore our Polymer Pyramid to guide you in selecting the best materials for your projects.

If you want to learn more about How to choose the right polymer for extruding, printing, or for other uses, check out our article on our support platform.

Yes, you can mix two polymers together using a filament extruder. This process involves melting both polymers and blending them into a homogenous mixture, which can then be extruded into a filament for use in 3D printing or other applications.

The resulting properties of the mixed filament will depend on the compatibility and chemical interactions between the polymers.

Yes, you can use additives and fillers in polymer materials. Common additives and fillers include plasticizers, antioxidants, colorants, reinforcing fibers, and nanoparticles. Additives are substances added to polymers to enhance specific properties such as strength, flexibility, UV resistance, flame retardancy, and more. Fillers are solid particles added to polymers to improve mechanical properties or reduce production costs. Check out this support article about Practical Tips when mixing additives to produce filament.

After each extrusion process, it is essential to ensure the Filament Maker remains equipped with safe and reliable materials, such as HDPE and PLA 4043D by NatureWorks. A small purging routine should be followed after every extrusion to maintain optimal performance to clear any residual material and prevent cross-contamination. It is highly advisable to conduct a more thorough purging of the machine every three weeks to maintain consistent filament quality and prevent potential blockages. For comprehensive maintenance, a deep purge should be performed on a monthly basis, ensuring the Filament Maker operates at its best and produces high-quality filaments for various applications.

If the filament maker experiences diameter fluctuations in the produced filament, it is crucial to investigate the environmental conditions first. Factors such as light and wind can significantly impact the extrusion process. Excessive exposure to direct sunlight or strong winds may lead to inconsistent heating and cooling of the filament, causing diameter variations. Therefore, it is advisable to ensure the filament maker is placed in a controlled environment with stable lighting and minimal air movement. Check out this article for more Causes of Filament thickness deviation and inconsistent diameter.

Feel free to reach out to us for assistance. Our dedicated support team is here to help. Submit your question, and we'll respond promptly with the answers you need. If you prefer to explore on your own, check out our Comprehensive support platform for a wide range of articles and resources that might address your query.

We do our best to reach out to you within 24 hours. Our opening hours are 09:00-17:00 CET from Monday to Friday.

From Our Blog

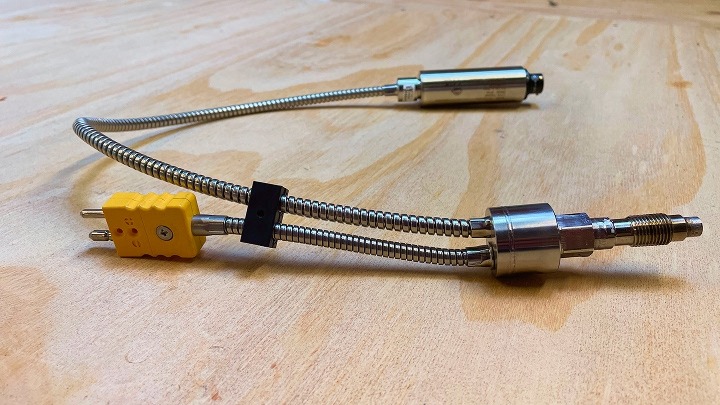

How We're Developing a Pressure Sensor for the Extrusion Process

Filament Maker TWO vs. Alternatives: Compare Filament Extruders

3devo 2024 Highlights: Reflecting on a Year of Growth and Change